What is M.2? Understanding the M, B, and B+M Key & Socket 3

It has been 13 years since the M.2 (pronounced “M dot two”) standard was introduced in 2012. Formerly known as the Next Generation Form Factor (NGFF), it was formally renamed to M.2 in 2013. The M.2 standard, a specification for internally mounted computer add-in cards, gained widespread adoption primarily because it offered enhanced performance, greater application flexibility, versatility across multiple interfaces, and compact form factors. M.2 provides higher performance and capacity while minimizing module footprint.

Turbo-Boosting the Speed Shift: SATA to PCIe NVMe

Created to overcome the limitations of the SATA 6 Gb/s link and to provide more options for small form factor cards, including solid state drives (SSDs) in different sizes and with different capacities, M.2 supports both Serial (ATA) and PCIe interfaces, which allows SSD manufacturers to provide and customize more performance as well as cost options.

While M.2 continues to support SATA SSDs, the rise of applications requiring high responsiveness, faster data transfer speeds, low latency, and improved power efficiency has steadily increased the demand for PCIe M.2 SSDs. These SSDs leverage up to x4 PCIe lanes and the Non-Volatile Memory Express (NVMe) protocol, which deliver massive performance leaps over SATA SSDs.

The table below presents an overview of speed evolution from SATA to PCIe’s latest iterations and their respective use cases.

| Interface | Max. Speed (2025) | Use Case | Reliability/Eccentricities |

|---|---|---|---|

| PCIe Gen6 x4 | 32,000 MB/s (theoretical) | R&D, next-gen servers | Engineering sampling, limited vendor support |

| PCIe Gen5 x4 | 16,000 MB/s | AI/analytics, high-performance computing (HPC) | Advanced supply, cooling a must |

| PCIe Gen4 x4 | 7,000 MB/s | Edge, databases, AI | Requires careful thermal design |

| PCIe Gen3 x4 | 3,500 MB/s | Legacy servers | Mature/stable, widely available |

| SATA | 600 MB/s | Legacy, rugged, field | Extreme longevity, broad vendor base |

PCIe 5.0 doubles PCIe 4.0’s data transfer rates from 16 GT/s to 32 GT/s per lane. Its adoption is growing rapidly in professional, high-performance, and artificial intelligence and machine learning (AI/ML) sectors where its higher bandwidth can be leveraged. Users can expect blazing-fast application loading, data processing, boot times, and content production. M.2 supports the latest high-speed interfaces like PCIe 6.0/5.0 and protocols like NVMe, but it continues to support PCIe 4.0/3.0, SATA, and USB 3.0 for backward compatibility. This allows users to integrate new hardware with existing systems, though the performance may be limited by the maximum speed of the older standard.

Sizes, Keys/Connectors, and Sockets: What the Nomenclature Means

M.2 modules come in different sizes and can also be utilized for wireless communication cards such as Wi-Fi® and Bluetooth® adapters. Other uses include near-field communication (NFC) modules, satellite navigation (GPS) modules, digital radio and WiGig wireless modules, and wireless wide area network (WWAN) modules for cellular network connectivity.

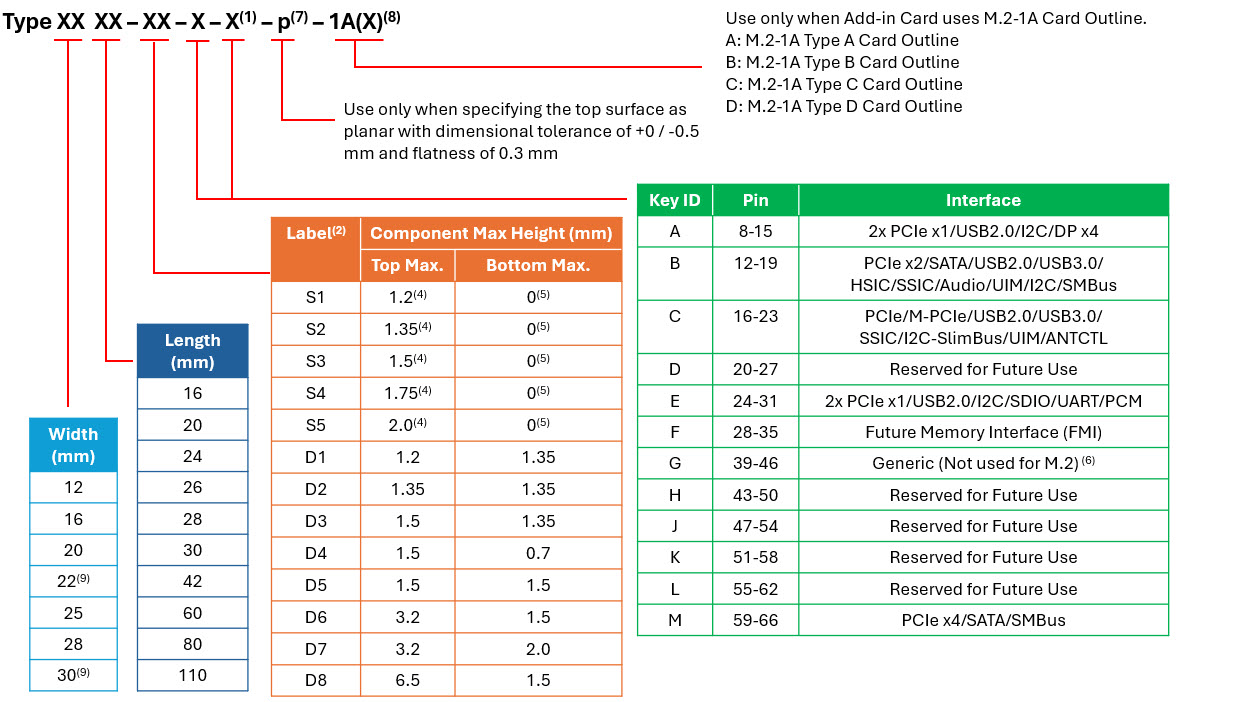

To ensure precise compatibility between different modules and motherboard sockets, the PCI Express M.2 Specification employs a standard naming convention.

M.2 Naming Nomenclature

The following table provides details of the M.2 Naming Nomenclature in the PCI Express M.2 Specification Revision 5.1.

- Use ONLY when a double slot is being specified.

- Label included in height dimension.

- This dimension is 11.5 mm but is written as 11 in Type name (i.e., BGA Type 1113).

- For BGA SSD, maximum height is measured with the solder balls collapsed and is valid whether the BGA is located directly on a platform or mounted on a module board.

- Insulating label allowed on connector-based design.

- Key G is intended for customer use. Devices with this key will not be M.2-compliant. To be used at customer’s risk.

- Use only when specifying the top surface as planar.

- Use only when Add-in Card current consumption requirements exceed 0.5 A per pin (normal Power Rating) and/or card outline is changed to an M.2-1A type.

- M.2-1A only supports widths of 22 mm and 30 mm.

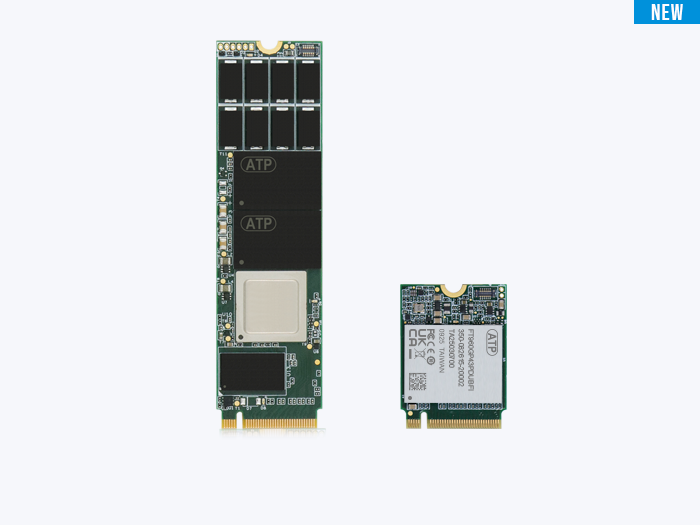

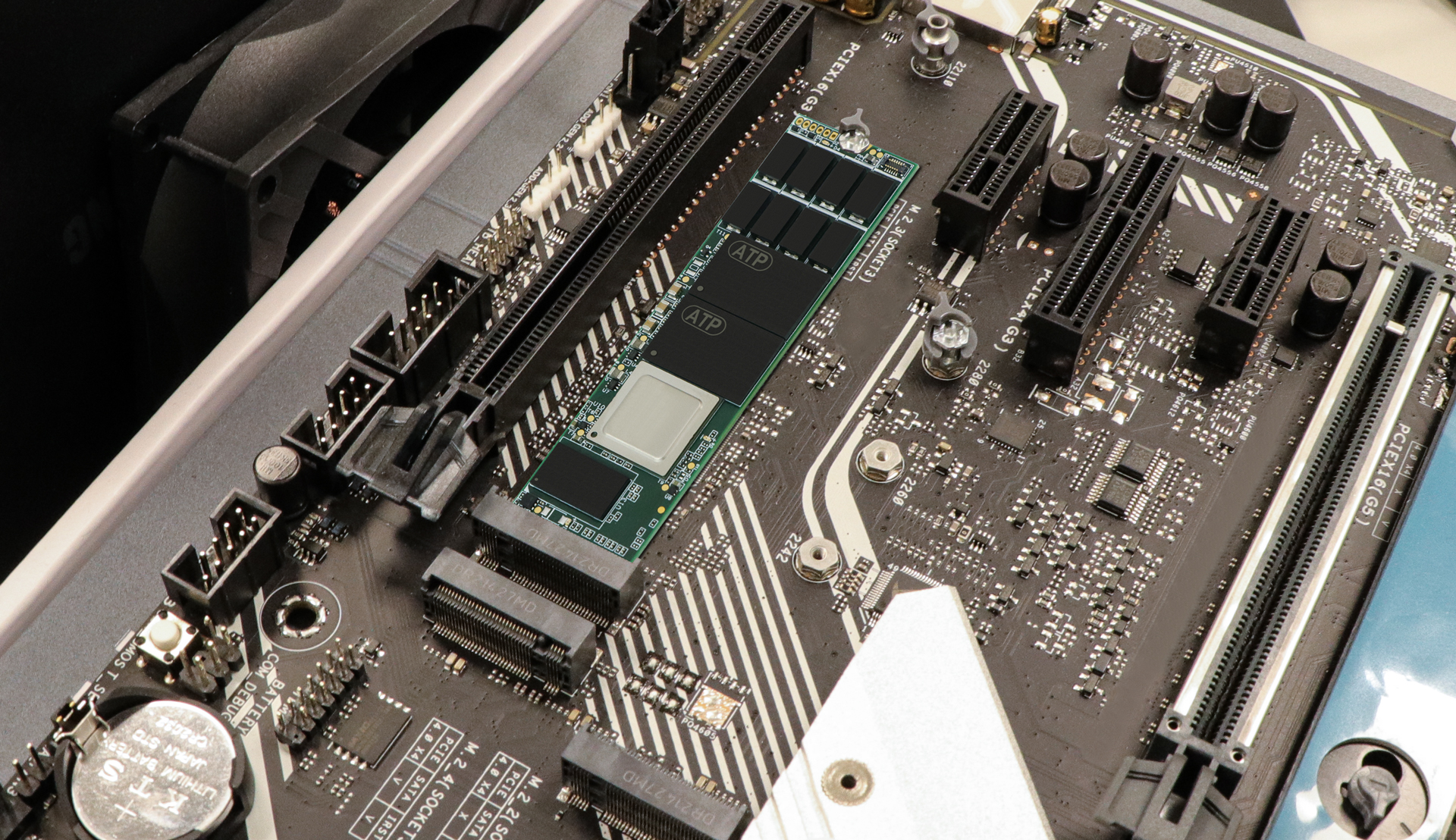

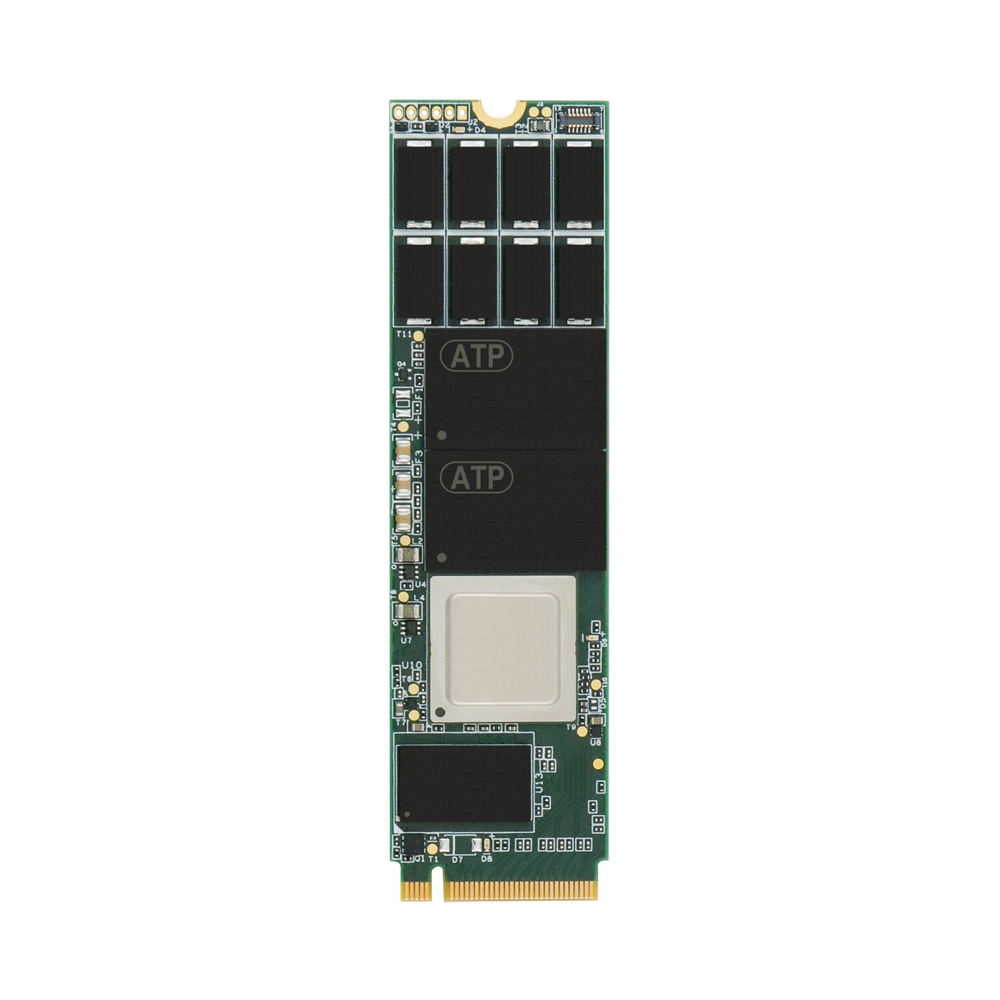

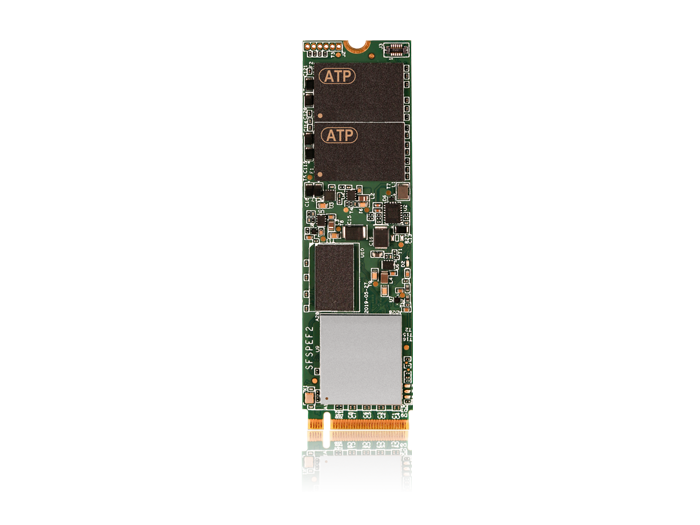

From the standard naming convention above, we can deduce the following information about this sample image, which shows an ATP PCIe® Gen4 NVMe M.2 2280-D2-M SSD:

|

2280-D2-M Width: 22 mm Height: 80 mm D2 Label: Double sided with component max. height of 1.35 mm (top and bottom) Key ID: M (PCIe x4) |

Sockets

To ensure proper installation of M.2 modules, the M.2 standard in the PCI Express M.2 Specification has clearly distinguished “sockets” on the host. Each socket has a unique mechanical key, and modules are not interchangeable between sockets.

- Socket 1: Connectivity socket for Wi-Fi®, Bluetooth®, NFC (near-field communication) or Wi-Gig.

- Socket 2: WWAN/SSD/Other Socket that will support various WWAN+GNSS (global navigation satellite system) solutions, various SSD and SSD Cache configurations, and other yet-undefined solutions. (If the motherboard has a Socket 2 for a WWAN card and it is not in use, the socket may accommodate a B+M-keyed small M.2 SSD. Please refer to your motherboard documentation for details).

- Socket 3: SSD Drive Socket with SATA or up to four PCIe lanes.

- Please refer to your motherboard documentation to make sure that your M.2 module fits and works with the corresponding socket on the motherboard.

- M.2 modules are neither hot-swappable nor hot-pluggable. Performing hot-swap or hot-plug may damage the modules and cause harm to the person performing this.

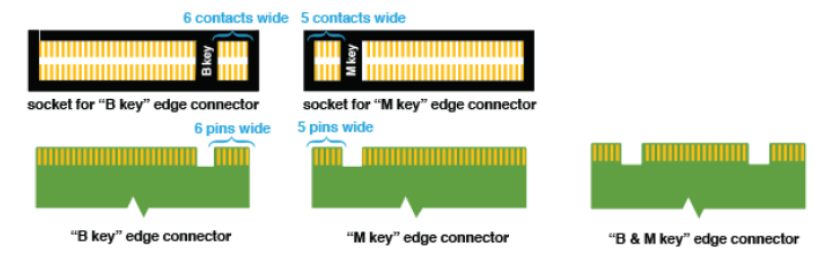

Keys/Connectors

The edge connectors on the M.2 modules are also called “keys.” They are used to prevent insertion into an incompatible socket on the host.

The M.2 specification identifies 12 key IDs on the module, but M.2 SSDs typically use three common keys: B, M, and B+M. You will find the key type labeled on or near the edge connector (or gold fingers) of the SSD.

The following table summarizes the key types typically used on M.2 SSDs, their physical characteristics (Key ID and Notch Position), typical use cases for ATP M.2 SSDs, main interface capabilities, PCIe lane counts, and common deployment scenarios.

| Key Type (Physical) |

Key ID (Label) |

Notch Position (Pin #) |

ATP’s Typical Use Cases | Main Interfaces | PCIe Lanes | Common Deployments | |

|---|---|---|---|---|---|---|---|

| B | Single notch | B | After pin 6 | Rugged/legacy builds | PCIe x2, SATA | Up to 2 | Gateways, field devices |

| M | Single notch | M | After pin 59 | High-performance SSDs | PCIe x4 (or 8) | Up to 4/8 | Servers, analytics, edge |

| B+M | Dual notch | B+M | Both | Maximum compatibility | PCIe x2, SATA | Up to 2 | Fleet upgrades, spares |

B Key is often used in rugged or legacy devices requiring moderate bandwidth.

M Key is characteristic of high-performance SSDs designed for demanding servers, analytics systems, and edge computing.

B+M Key offers broader compatibility with devices accepting either key type but are limited to PCIe x2 lanes or SATA speeds, thus offering moderate bandwidth.

To leverage higher PCIe interfaces like Gen 4/Gen5, M-keyed SSDs can ensure maximum bandwidth with support for up to PCIe x4/x8 interfaces, as well as better handling of the thermal envelope (the heat generated by blazing-fast, high-speed data transfers) through a combination of advanced hardware and firmware thermal management.

ATP’s M.2 Modules

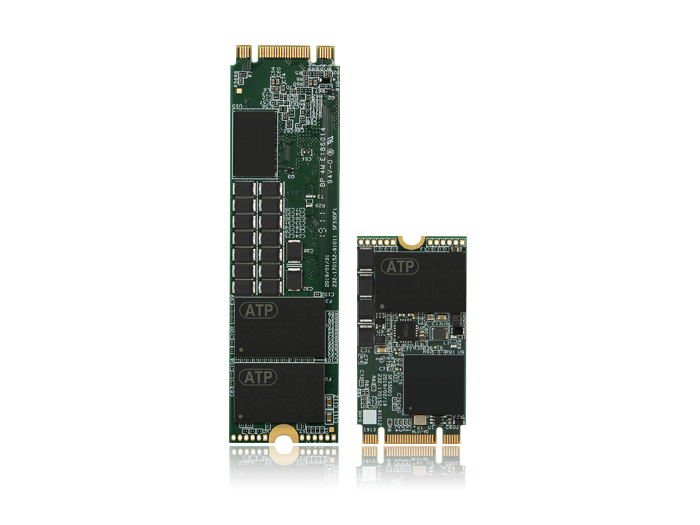

ATP’s M.2 modules are available in the following form factors:

| Connectorized | PCIe NVMe | |

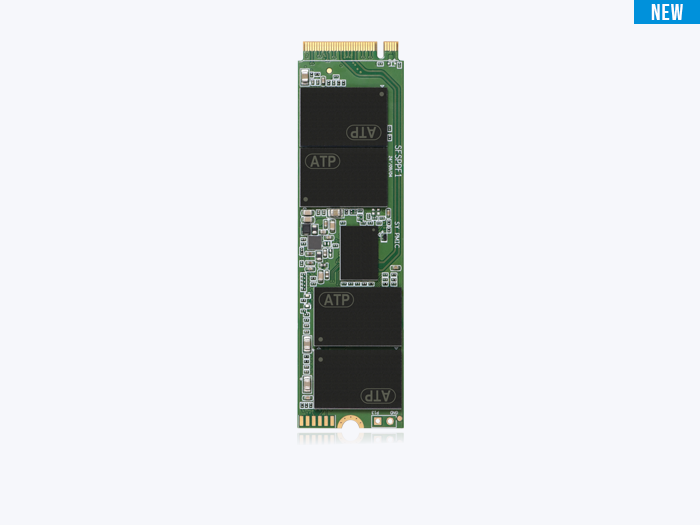

M.2 2280 PCIe Gen4 x4 Interface M Keyed |

M.2 2280, 2242, 2230 PCIe Gen3 x4 Interface M Keyed |

|

| SATA | ||

M.2 2280, 2242 SATA Interface B+M Keyed |

||

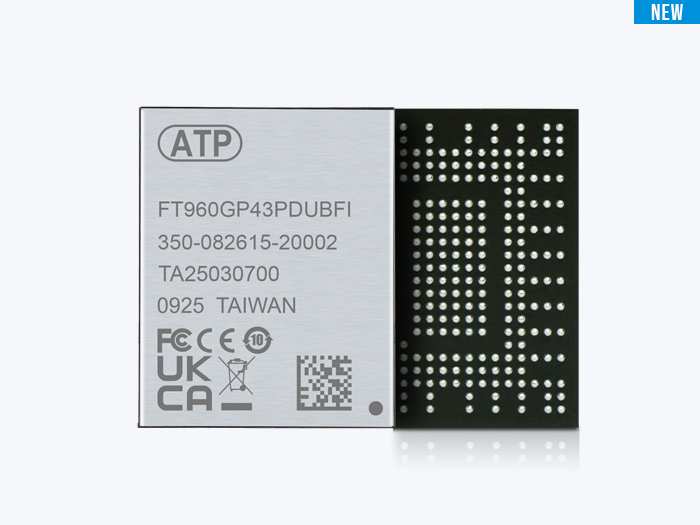

| Soldered Down |  PCIe M.2 Type 1620 HSBGA |

|

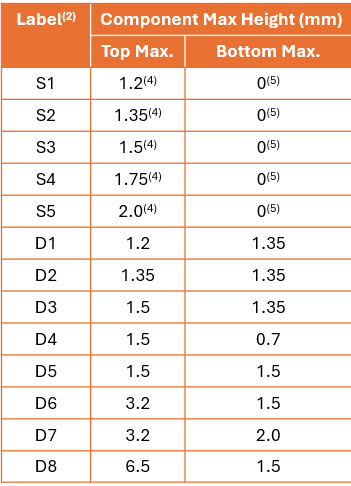

Labels: Single- or Double-Sided?

In the nomenclature table, the labels S1 to S5 and D1 to D8 indicate the maximum allowed component thickness and whether the module is single-sided or double-sided. When components are installed on only the top side of the module, they are “single-sided” (S1 to S5) while “double-sided” (D1 to D8) refers to modules installed with components on the top and bottom. Double-sided modules can accommodate more NAND chips to effectively expand capacity without altering the overall M.2 dimensions. The labels ensure compatibility with host devices that may have limited vertical clearance.

| SSD Type | Sides with Chips | Typical Max. Capacity | Clearance Needed |

|---|---|---|---|

| Single-sided | 1 (top) | 2–4 TB | Lower (easier fit) |

| Double-sided | 2 (top and bottom) | 4–8 TB+ | Higher (may need extra room) |

Keeping It Cool: Intelligent Thermal Management

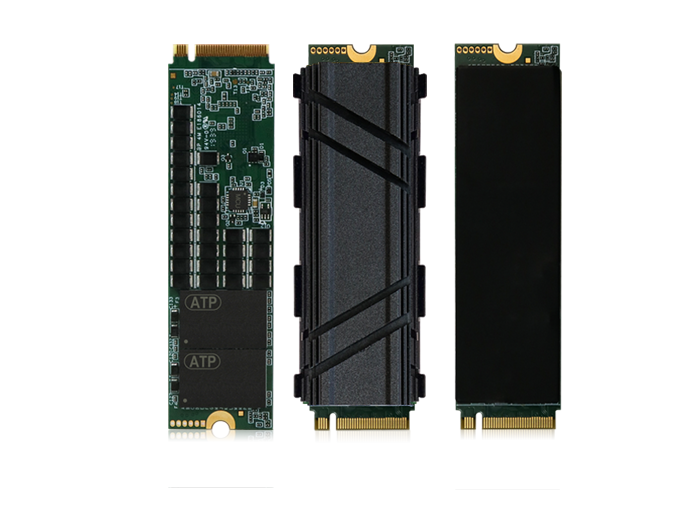

M.2 SSDs, especially those supporting PCIe Gen4/Gen5, can achieve very high sequential read/write speeds, generating significant heat. If unmanaged, this could cause performance degradation and shorten the SSD lifespan.

The small form factor allows the integration of thermal solutions, such as specialized heatsinks that effectively dissipate heat away from the SSD’s critical components like the controller and NAND chips. Double-sided modules maximize the surface area within tight spaces and allow the installation of more components while optimizing air flow within the system.

Firmware-based dynamic thermal management standardized under NVMe specifications, such as the Host Controlled Thermal Management (HCTM), enables M.2 SSDs to monitor their temperature through SMART attributes and automatically adjust performance. This adaptive technology prevents overheating, thus balancing performance with thermal management, sustains peak performance in demanding tasks, and extends the SSDs lifespan.

- System, Mechanical Design, and Performance Criteria. Heatsinks must match the size and thickness of the M.2 SSD. It is important to check if the heatsink is designed for single- or double-sided modules, as height/vertical clearance within the host system is an important consideration. Airflow within the system, user applications, and workload/performance requirements must also be carefully considered.

- Material and Design. Aluminum or copper? Finned or grooved? It is crucial to take into account which options deliver improved thermal conductivity.

- Installation Mechanism. How will the heatsink mount to the SSD? Common options include clips and screws. Choose a secure but gentle mounting that will not physically damage or pressure the SSD and its printed circuit board (PCB)

While heatsinks do not affect the electrical keying or socket interface of the M.2 SSD, some heatsink designs will add physical height and bulk, which can interfere with adjacent motherboard components or cover the M.2 slots. Also, for extremely compact systems with strict space constraints, thicker or dual-sided heatsinks may obstruct the space around the socket area, which may limit compatibility or installation.

When choosing M.2 heatsinks, consider form factor compatibility, thermal efficiency, installation method and device clearance.

ATP’s Heat Dissipation Solutions: Thermal Joint Validation Service

ATP’s heat dissipation solutions involve a continuous evaluation of our mechanical designs. This includes examining materials, appearance, airflow, and assembly processes to ensure optimal thermal management.

Thermal solutions experts at ATP know that one size does not fit all. Under the ATP Thermal Joint Validation Service, the unique thermal challenges for different use cases and scenarios are meticulously considered, and holistic as well as customizable solutions combining firmware and hardware technologies are offered to meet specific thermal requirements.

Below is a table detailing the solutions we offer for M.2 SSDs.

| Form Factor | HSBGA | M.2 2280 | |||

|---|---|---|---|---|---|

| Capacity | Up to 512 GB | Up to 1920 GB | |||

| Heatsink Type | Copper Heatsink | Copper Foil | 4 mm Fin-Type Heatsink | 8 mm Fin-Type Heatsink | |

| Dimension: L x W x H (mm) | 16 x 20 x 1.6 | 80 x 22 x 3.9 | 80 x 24.4 x 8.3 | 80 x 24.4 x 12.3 | |

| Material | Cu with Ni/Cr plating | Copper | Upper: Aluminum alloy Bottom: Stainless steel |

||

| Suitability | Limited space | Enough space for effective heat dissipation | |||

| Assembly | Molding | Adhesive | Clips design | ||

Conclusion

Over a decade since it was first introduced, the M.2 standard continues to gain widespread adoption for enabling compact form factors, enhanced performance, and broad versatility, not only for SSDs but for other internally mounted computer add-in cards.

Leveraging the latest high-speed PCIe interface, M.2 SSDs deliver data transfer speed enhancements over the previous generation while offering backward compatibility across different interface protocols and older generations, allowing users to integrate new hardware with existing systems.

The broad ecosystem of keys, sockets, and thermal solutions ensures that M.2 meets the evolving needs of present as well as future systems and applications. By continuing to offer significant advantages over traditional storage media and as PCIe continues to advance, M.2 SSDs will remain an important enabler in applications where speed, space, and energy efficiency are critical.

For information and inquiries about ATP’s M.2 SSDs, please visit the ATP website or contact an ATP representative in your area.