In a moderate climate, vehicles can run at optimal temperatures, with cool air passing through radiators. The airflow cools efficiently, keeping the engine running at full speed. But in a scorching desert, hot air reduces cooling effectiveness, causing the engine to overheat. Similarly, the digital world is fast becoming a digital desert and solid state drives (SSDs) are constantly being pushed beyond their safe operating temperature limits.

What happens when SSDs operate under excessive heat?

- The tunnel oxide in floating gates weaken, causing electron leakage and increasing bit errors.

- The overall lifespan of the SSD is significantly reduced.

- Conventional self-cooling mechanisms drastically reduce clock speeds, which slows down read/write speeds.

- The system becomes unstable or crashes unexpectedly as performance starts fast and then abruptly slows down, swinging between hot and cold.

- Permanent hardware damage or complete drive failure and data loss.

The Burning Truth About Traditional Thermal Throttling

Controller and NAND flash chips generate heat under heavy workloads, making NVMe PCIe SSDs prone to overheating due to their high speeds and power consumption. Large data transfers, simultaneous programs running, and other resource-intensive tasks contribute to increased heat.

The constrained spaces where the SSDs are installed further aggravate heat generation, as airflow is potentially blocked by other components that also generate heat. As more components are installed within the system, heat may be trapped and not dissipated effectively.

To prevent overheating, thermal throttling is activated automatically. This is a protective mechanism that reduces the drive speed to cool the SSD. Typically, thermal throttling solutions adjust performance in only two or three stages, causing abrupt performance drops. With traditional solutions lacking granular control and having fewer levels of performance adjustment, jumps or drops in throughput are noticeable and may cause potential timing issues in sensitive systems.

The ATP Solution: Ace Thermal Throttling Offers Precise 18-Gear Advantage

What if your vehicle running at high speed in the scorching desert only had three speed settings. When you step on the gas pedal, the car would suddenly speed up, abruptly slow down repeatedly, making it very difficult to maintain a steady speed and a safe engine temperature.

ATP Ace Thermal Throttling (AceTT) uses finely tuned, incremental adjustments of up to 18 stages instead of the typical two or three stages in traditional thermal throttling solutions. It is like having a finely tunable gas pedal — it allows the “engine” (SSD) to smoothly and steadily adjust its speed to maintain safe temperatures without sudden jumps. This ensures stable performance and longevity even under challenging thermal conditions.

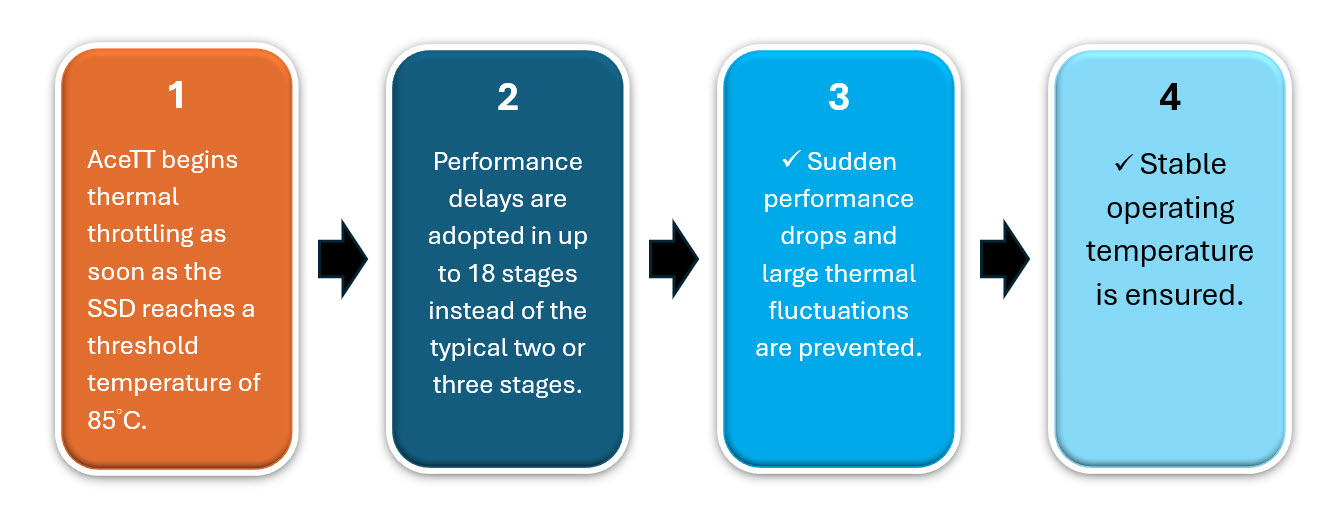

How AceTT Works

AceTT begins the finely tuned throttling stages when the SSD reaches or exceeds the temperature threshold of 85°C to carefully limit further temperature increase.

The incremental throttling maintains a stable operating temperature in contrast to large, sudden changes that cause rapid swings between high and low performance, sudden temperature spikes followed by drastic large drops, and inconsistent performance that reduce user experience during thermal throttling.

Proof is on the Dashboard: Thermal Equilibrium

AceTT offers very fine-grained control of graduated performance reductions of up to 18 stages. With AceTT, the goal is not only to prevent overheating, but to achieve thermal equilibrium, enabling SSDs to perform with superior operational stability, smoother performance, and steady temperatures even at high speeds.

Breeze Through the Heat With Multi-Stage Precision

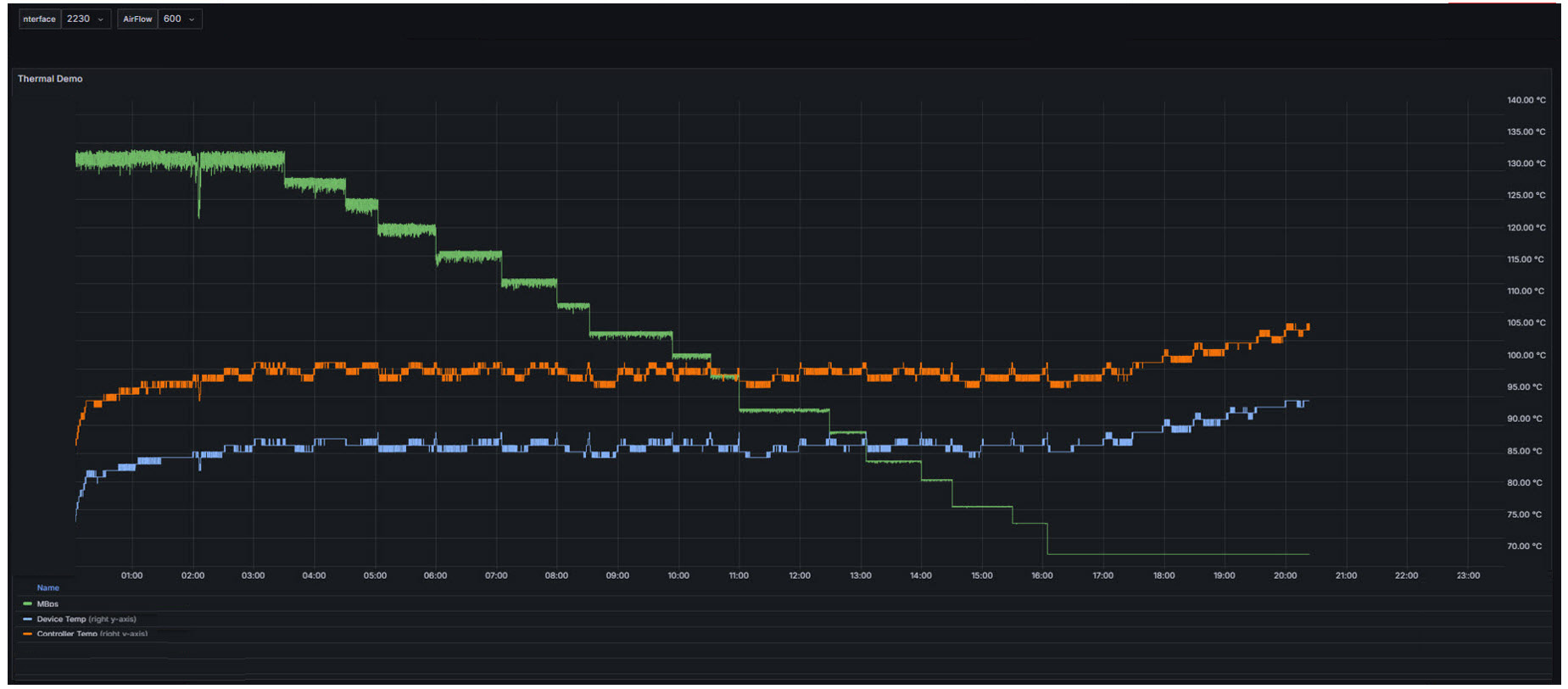

The following graph is a visual demonstration of how the multi-stage behavior is deliberately triggered by chamber‑controlled ambient heating. As temperature rises, a multi‑stage thermal‑throttling scheme tapers performance behavior to prevent abrupt speed or temperature swings.

The green line represents throughput/performance declining in a series of steps instead of sharp drops. As the controller (orange line) and device (blue line) temperatures pass the predefined threshold, one stage of the AceTT scheme is triggered. While the internal temperature rises steadily, the rise is moderated, and the gradual tapering ensures that performance remains predictable and smooth as the SSD adjusts its speed and power output incrementally.

To emulate a 55°C ambient temperature while the device operates near the 85°C range, AceTT brings the SSD operating in TLC mode to thermal equilibrium (steady state) across phases and maintains steadier, optimal performance with minimal airflow fluctuation.

When the Heat is On, Bring it On! AceTT: Steady and Controlled at High Speeds

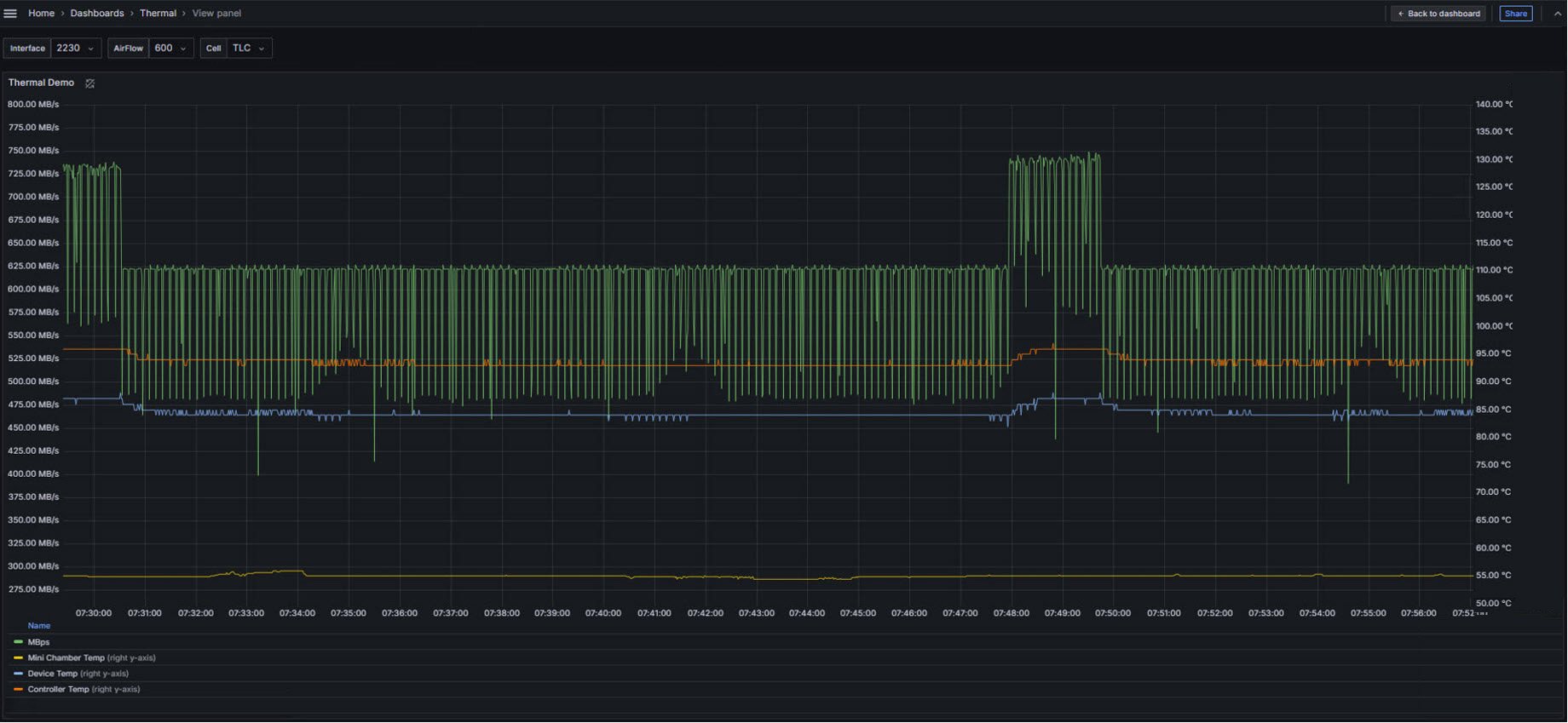

The following graph shows how the device maintains steady performance while keeping temperature variations controlled across extended phases of operation. Throughput (represented by the green lines) remains largely consistent except for short, controlled performance drops. The orange (controller temperature) and blue (device temperature) lines represent different temperature readings, showing near thermal equilibrium where sudden overheating or abrupt temperature changes are prevented even while the SSD performs at high speeds.

AceTT Benefits

Implemented through ATP’s engineering capabilities and broad industrial experiences in understanding diverse contexts and challenges, AceTT offers the following benefits, especially for industrial and embedded environments.

- Optimal Performance under sustained workloads and high operating conditions.

- Mitigation of Sudden Heat Spikes and Drops that cause inconsistent performance.

- Longer Device Life as the SSD is protected from the damage of overheating, thus ensuring longer product lifespan.

- Stable Operating Temperature for steadier and more reliable operation, which prevents heat-induced read/write errors and data corruption.

Advantages of AceTT Over Traditional Thermal Throttling

- Fine-grained control for optimal temperature and performance balance

- Smooth, progressive performance reduction avoids abrupt drops and minimizes impact on throughput

- Maximized device reliability under varied thermal conditions

- Dynamically adapts to complex environments and workloads

- Highest operational stability and preserves steady operation

Summary

ATP Ace Thermal Throttling is a new feature that intelligently manages the temperature of NVMe PCIe SSDs. These SSDs deliver blistering-fast performance but may be prone to overheating especially when tackling heavy workloads and installed within systems that do not have sufficient airflow or efficient cooling systems.

Like vehicles driving in the desert with limited speed settings, traditional thermal throttling solutions with only two or three stages lead to abrupt performance drops, while AceTT’s 18-stage gearbox allows for smoother, more incremental adjustments to maintain not only safe operating temperatures but steadier, more consistent performance.

By achieving thermal equilibrium, AceTT prevents SSDs from overheating, extends their lifespan, and ensures reliable operation in demanding conditions, especially in mission-critical environments where consistent performance and long-term reliability are essential.

For more information on the ATP Ace Thermal Throttling, visit the ATP website or contact an ATP Representative in your area.