|

The Challenge

Handheld computers are essential productivity tools in several industrial applications that require portability and compact form but with enterprise-level performance and rugged durability. Some of these specialized applications include transportation and logistics, warehousing, manufacturing, retail, postal or parcel deliveries, and more. An ATP customer needed a high-endurance storage device for their rugged handheld computers that aim to improve workflow and boost productivity at low total cost of ownership (TCO).

The Solution

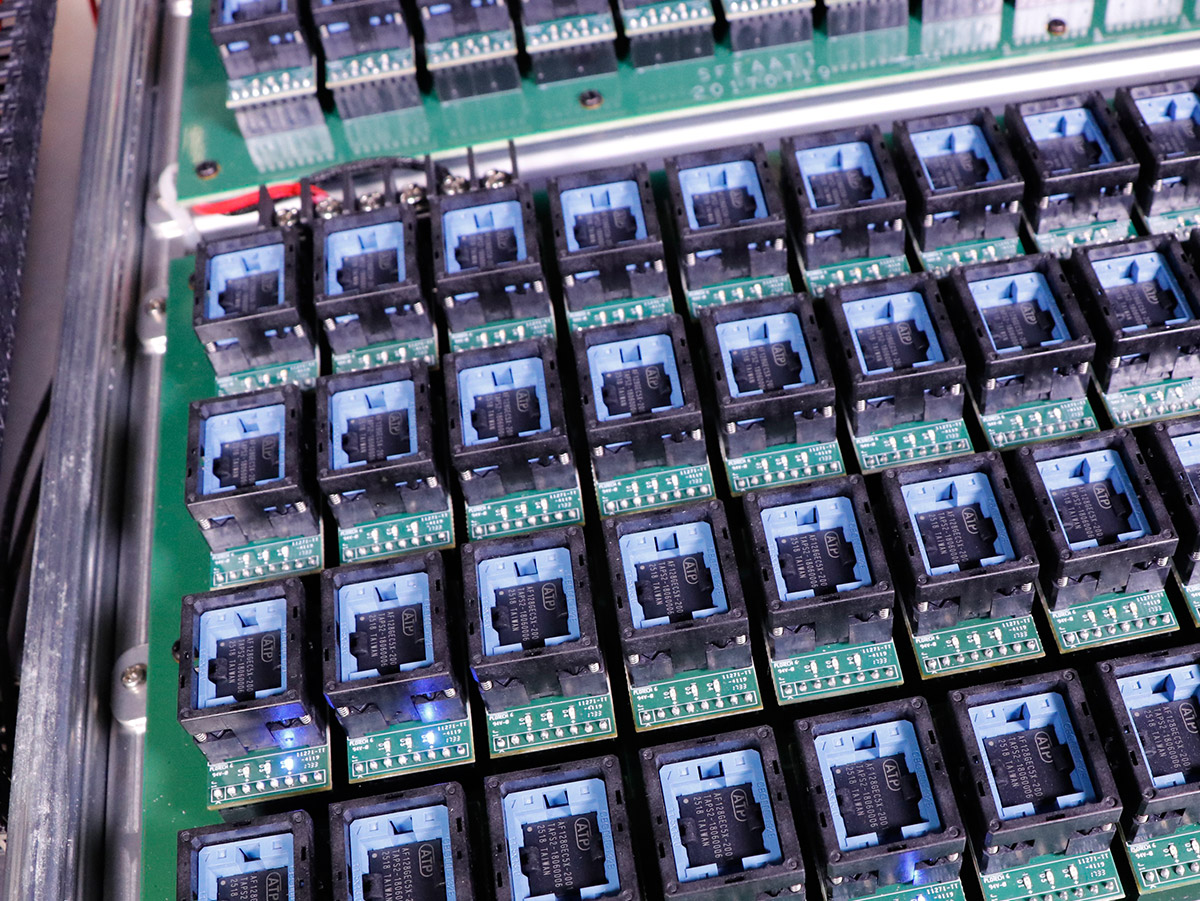

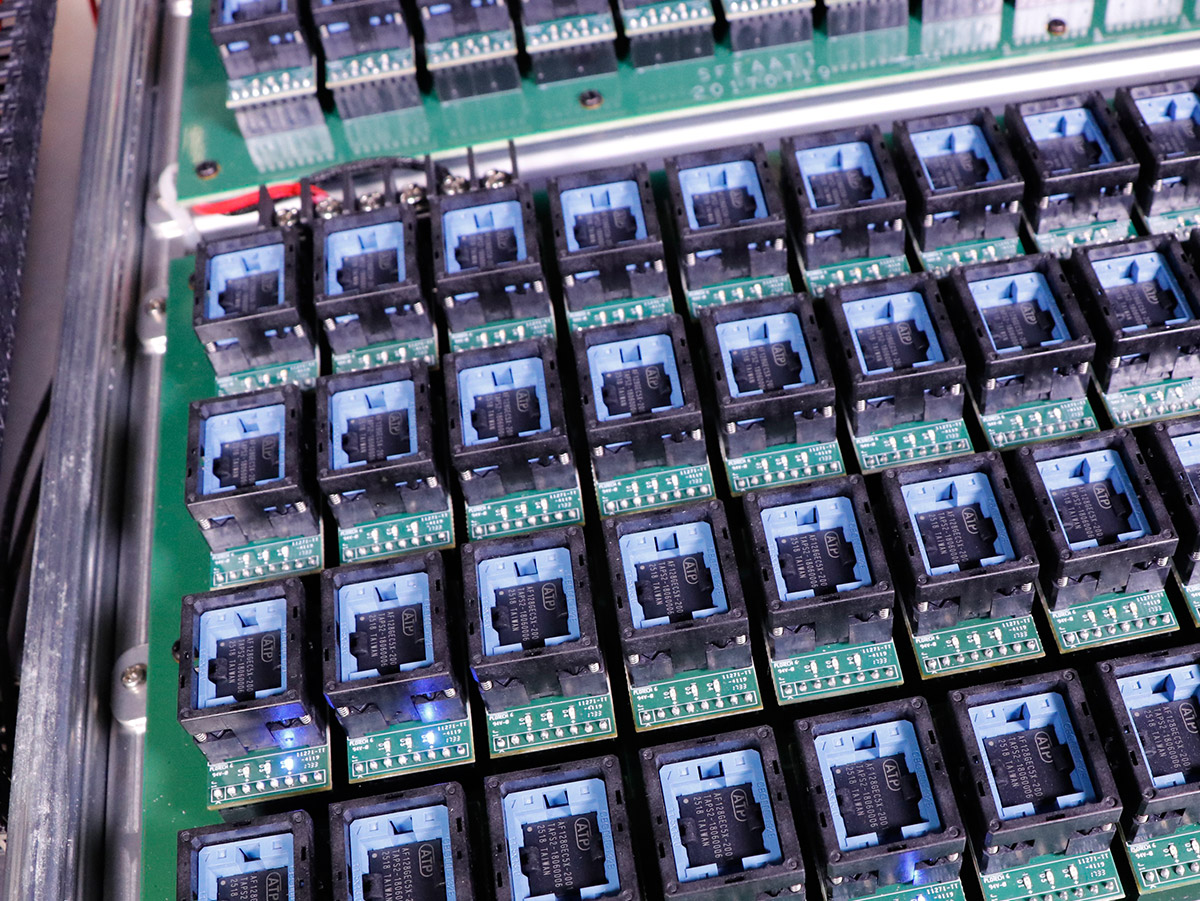

To meet the customer’s requirement for the storage device’s extended endurance, ATP used its own-designed Rapid Diagnostic Testing (RDT) to filter/characterize the e.MMC according to different criteria based on application requirements. The RDT process began with IC-level characterization beyond JEDEC standards to ensure the reliability of the new die. The design/layout, controller, hardware and firmware were validated at product level using ATP-designed/built testers. Stress accelerants such as temperature, power/voltage and other factors are used to identify qualified/unqualified blocks intended for the customer's specific application needs. Finally, production quality screening ensures the e.MMC’s reliability by detecting and removing weak blocks and ICs.

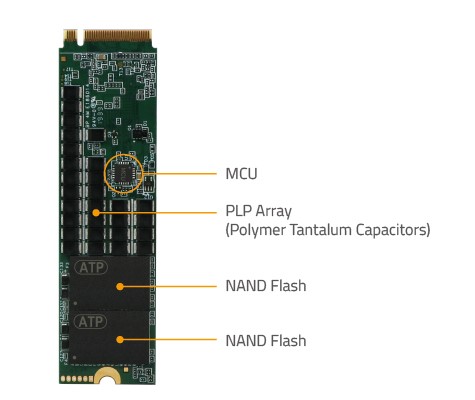

Employing SLC Mode NAND flash also improved the performance, reliability and endurance the ATP e.MMC, thus providing reliable data storage without prohibitive costs. ATP also performed Joint Validation testing to ensure compatibility with the customer’s host platform. This consisted of compatibility and function tests with customer-supplied host devices and systems to proactively detect bugs and failures.

The Result

Through stringent RDT testing and the use of SLC Mode NAND flash, ATP successfully achieved an average of 50K P/E cycles to meet the customer’s high-endurance requirement. This is significantly higher than the endurance ratings of other standard NAND flash technologies such as 2D/3D MLC (25-30K) and 3D MLC (30-40K). With these achievements, the ATP e.MMC provides excellent performance for the customer’s handheld computers at the best TCO value.

|