Industrial SSD procurement demands more than just comparing price-per-gigabyte; it requires navigating the inherent physical volatility of the storage medium itself. At a microscopic level, NAND flash cells function like tiny rechargeable batteries that naturally 'leak' their stored data over time—a process drastically accelerated by high temperatures and frequent usage. While commercial SSDs offer an attractive upfront price, they effectively use 'batteries' with thinner insulation, leading to rapid data corruption and device failure when exposed to the heat and stress of industrial environments over time.

For procurement teams, ignoring this physics reality transforms a short-term 'cost saving' into a high-TCO liability characterized by frequent replacements and unscheduled system downtime. To bridge the gap between engineering needs for reliability and procurement targets for longevity, it is critical to select SSDs expressly built to counter this volatility. We break down these distinctions by the nuanced, real-world scenarios that don’t necessarily appear on a BOM or standard spec sheet.

Bridging the Gap: From Spec Sheet to Real-World Reality

Before we dive into the technical details, it is important to acknowledge the disconnect that often exists between an engineering request and a procurement order. Engineers live in a world of "worst-case scenarios"—power spikes, heat waves, and 24/7 distinct workloads. Procurement lives in a world of "standardized specifications"—GB capacities, interface speeds, and unit costs.

The friction occurs when a commercial drive meets the standard specs but fails the worst-case reality. The following guide is designed to translate those hidden engineering risks into clear commercial questions. By asking these questions upfront, you can ensure that the "cheaper" option doesn't become the most expensive mistake in your supply chain.

Why do SSDs need power loss protection?

Engineers request SSDs with Power Loss Protection (PLP) because industrial systems often face unstable power grids, voltage fluctuations, or sudden outages. To achieve high speeds, SSDs don't write data directly to the permanent flash storage (NAND) immediately. Instead, they first park data in a high-speed, temporary cache called DRAM.

The problem is that DRAM is volatile—it needs constant electricity to hold information. If power cuts out while data is sitting in this DRAM "waiting room," that data vanishes instantly. If the missing data happens to be the drive's Flash Translation Layer (FTL)—the drive's internal address map, the SSD won't just lose a file; it can become completely unreadable ("bricked").

Hardware Power Loss Protection (PLP) solves this by acting like a tiny backup battery for the SSD. It uses capacitors to hold just enough charge to let the drive finish writing its data safely, preventing corruption.

Why ATP go the extra mile for Power Loss Protection

We don't just add capacitors; we add a dedicated "brain" (MCU) to support the primary controller, DRAM and capacitors for power-related matters. This MCU controller can actively monitor power quality 24/7. It acts as a surge protector, a battery manager (checking capacitor health), giving you better reliability not just into power events but accelerating power-off to power-on transitions, reducing system lag, improving availability, and supporting rapid recovery in edge or mission-critical applications.

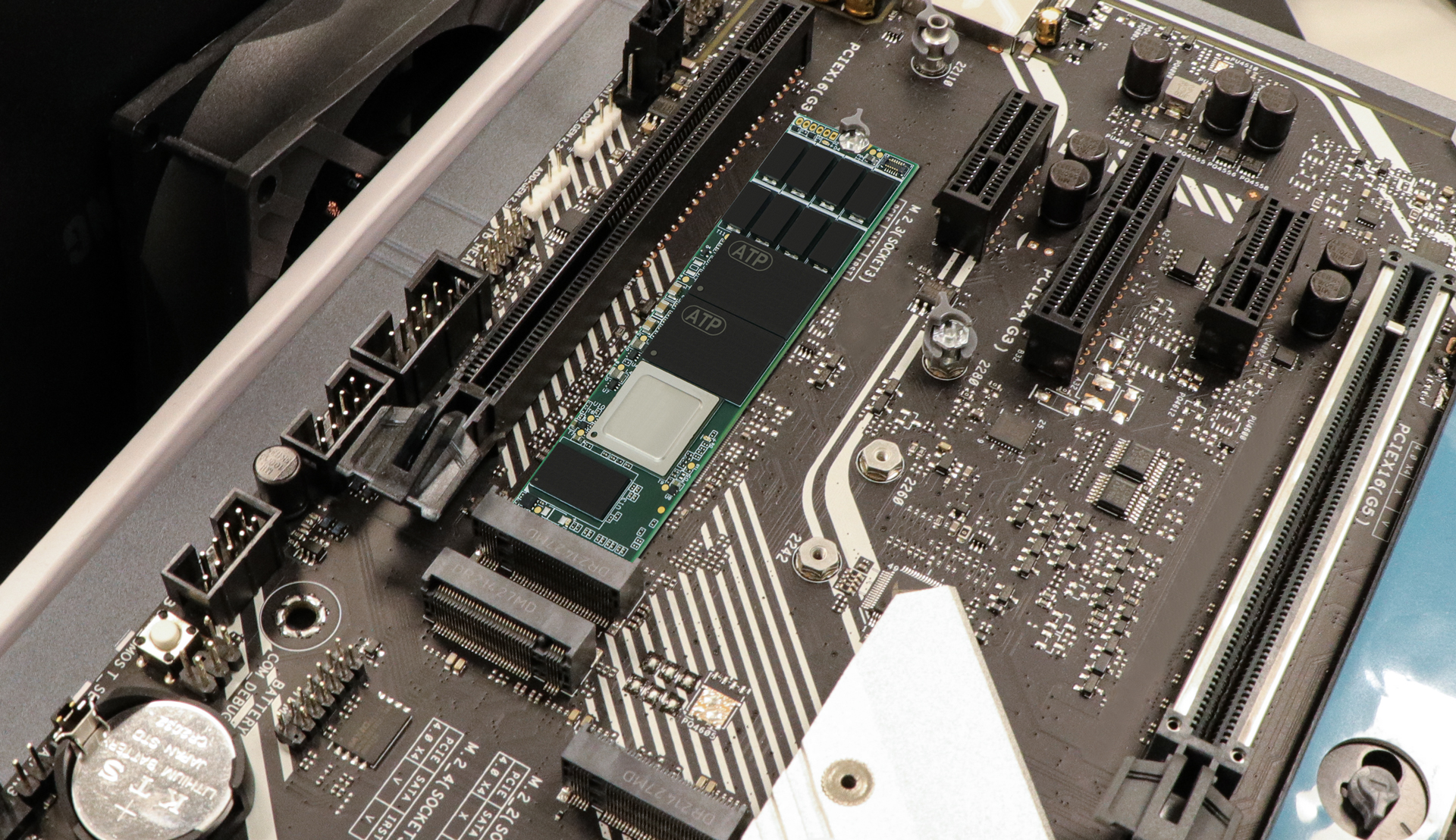

Circuit overview of an ATP SSD with HW+FW PLP

Learn more about ATP's wholistic solution to sudden power loss events in this article:

How ATP Provides HW/FW Power-Loss Protection for Your Data and SSDs

Is getting an I-Temp SSD enough?

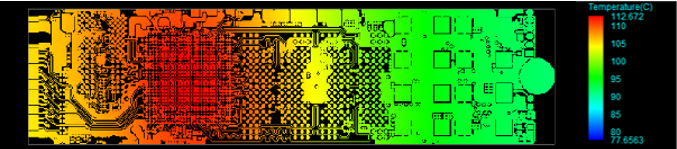

Simply seeing "-40°C to 85°C" on a datasheet is not enough. "I-Temp" often just means the drive survives sitting in those temperatures, not necessarily working reliably while the temperature is rapidly changing.

The real danger is Cross-Temperature stress. This happens when data is written at one temperature (e.g., a cold morning startup at -20°C) but read back at a completely different one (e.g., after the machine heats up to +70°C). This thermal gap physically shifts the voltage needed to read the data, leading to read errors and system crashes.

Procurement Checklist for Temperature:

-

Check the Definition (Ambient vs. Tcase):

Does the rating apply to “Ambient” (room air) or “Tcase” (surface of the drive)? A drive inside a metal box will be much hotter than the room air. -

Verify Airflow (LFM) Requirements:

Does the spec sheet assume active cooling? Check the Linear Feet per Minute (LFM) requirement. If your system is fanless (0 LFM), an I-Temp drive might still overheat because it cannot dissipate its own self-generated heat. -

Verify Cross-Temp Validation:

Ask if the vendor tests for “Cross-Temperature Robustness.” This ensures the firmware can automatically adjust its reading voltage (like focusing a lens) to recover data written in the cold but read in the heat. -

Sensor Placement:

Ensure the thermal sensor is placed near the critical components (NAND/Controller) to trigger protective throttling correctly, rather than in a cool spot that masks overheating.

An example of heat distribution simulation result of a PCB's top layer

Learn more:

SSD Temperature Specs: What the Numbers Really Mean

ATP AcuCurrent: Innovative Signal Integrity Optimization Technology

Will the SSD be used primarily for booting the system or for storing data?

This is a critical topic that often gets lost in technical jargon, but fundamentally, the goal is simple: the SSD must outlast the system it powers. To ensure this, we need to match the drive's endurance not just to a generic spec sheet, but to the actual job it will perform. We generally split industrial drive usage into two primary categories, each with its own "killer" stress factor:

-

Boot Drives (Read-Intensive):

These drives hold the Operating System (OS). While they don't face heavy write traffic, they face a different threat: Read Disturbance. Constantly reading the same OS files (like during boot-up or background checks) can physically degrade nearby data, leading to corruption in both "hot" (frequently read) and "cold" (rarely touched) areas. For these drives, the procurement priority isn't high write endurance, but Data Retention and Integrity features. -

Data/Storage Drives (Write-Intensive):

These drives bear the brunt of saving your application's data. Engineers often request these based on TBW (Terabytes Written) or DWPD (Drive Writes Per Day), but these numbers can be misleading if taken from a standard commercial spec sheet. A reliable endurance rating must account for the "messy" reality of industrial work—including Write Amplification (WAF) from random data patterns, extreme temperatures, and 24/7 active use. Buying a drive without validating these specific "real-world" stressors is a recipe for premature failure.

Learn more:

SSD Endurance Specs: Why the Numbers Do Not Tell the Whole Story

Simulating SSDs Payload Diversity and Realistic Usage

The spec sheet shows high speed, but will it last in the real world? (Burst vs. Sustained)

Not all speed is created equal. The impressive numbers on a datasheet usually represent Burst Performance—a short sprint achievable only for a few seconds using temporary cache. For industrial use, you must distinguish between "Sprinters" and "Marathon Runners."

- Burst Performance: Great for boot-ups or quick file transfers. It relies on a temporary "SLC Cache" to hit peak speeds.

- Sustained Performance: Critical for 24/7 logging or video recording. Once the cache fills, a standard drive's speed can decrease significantly. Industrial drives are validated to maintain a steady "minimum speed" for continuous operation.

Learn more:

Understanding the SSD Cache: The Key to Optimizing SSD Performance

My system is battery-powered or fan-less. Can NVMe SSD power be tuned to prevent overheating?

Yes, and this is critical because Power, Performance, and Thermals are inextricably linked.

Standard SSDs run in "race mode"—consuming maximum power to hit peak speeds. This generates significant heat, which must be dissipated. In industrial designs with limited airflow (Low LFM) or sealed fan-less enclosures, this heat has nowhere to go.

The result is Thermal Throttling: the drive hits its safety limit and drastically cuts speed to survive. For a mission-critical logger, this sudden performance collapse is often worse than having a slower drive to begin with. One of the solution, is to tune the drive's power consumption at the source, ensuring it never generates more heat than your chassis can dissipate. Here are the four levels of optimization:

1. Power State Adjustment (APST)

The drive's Automatic Power State Transition (APST) can be configured with aggressive sleep timers. This forces the SSD to drop into a near-zero power state the instant it stops writing, which is critical for extending battery life in devices that sit idle between tasks.

2. Reducing PCIe Lanes

Most industrial data doesn't require the full bandwidth of a 4-lane connection. Firmware can disable unused PCIe lanes (running x2 or x1 instead of x4), physically cutting interface power consumption by up to 50% without impacting typical logging or boot workloads.

3. Lowering Flash Clock Speed

For fanless systems where heat is the primary constraint, the internal frequency of the flash chips can be lowered. This acts as a hard "governor" on the SSD, guaranteeing it stays cool and never exceeds a specific wattage, regardless of the workload intensity.

4. Adjusting Drive Strength & Interleaving

Fine-tuning the microscopic behavior of the chips offers the final layer of efficiency:

- Drive Strength: Reduces the electrical signal power to the bare minimum needed for data integrity.

- Interleaving: Limits how many flash chips activate simultaneously.

Learn more:

AceTT: Conquering Digital Deserts With up to 18 Stages of Thermal Throttling

NVMe SSD Thermal Management: What We Have Learned from Marathons

How to Qualify an SSD Partner for Your AVL

Choosing a manufacturer for your Approved Vendor List (AVL) is about more than just picking a part.

In the industrial sector, the "best" SSD is useless if it disappears from the market in six months or fails in a way the vendor cannot explain. Beyond basic product specs, here is the due diligence checklist for adding a true industrial partner to your AVL:

- Supply Chain Transparency:

Does the vendor guarantee a Fixed Bill of Materials (BOM) down to the specific flash and controller? Do they have a clear Product Change Notification (PCN) policy that gives you months of warning before any changes? A partner must provide a long-term roadmap (3–5 years) to align with your own product lifecycle. - Engineering & Customization Depth:

Off-the-shelf testing is rarely enough. Does the partner have the in-house capability to customize firmware and run validation tests that mimic your specific environment—such as rapid power-cycling, thermal shock, or specific workload tuning? This "design-in" support is critical to ensuring the SSD works in your system, not just on their test bench. - Advanced Failure Analysis & Debugging:

In the real world, "failures" are rarely simple dead drives. They are often complex, intermittent "corner cases" where the SSD and host system stop talking. Does the vendor have the technical prowess to replicate failures in their lab? You need a partner who can analyze the root cause and even deliver a tailored solution that fits the host behavior and protocols

The Bottom Line: Procurement as a Strategic Advantage

Ultimately, buying industrial SSDs is not about paying more for the same capacity; it is about paying for certainty.

When you choose a drive with Power Loss Protection, Cross-Temperature validation, and a Fixed BOM, you aren't just buying storage hardware. You are buying insurance against field failures, protection against unannounced component swaps, and the guarantee that your product will perform as reliably in Year 5 as it did on Day 1. By shifting the conversation from "Price per GB" to "Total Cost of Ownership," procurement teams stop being just purchasers and become strategic guardians of product quality and brand reputation.

At ATP Electronics, we don't just sell SSDs; we strive to build this certainty. With over 30 years of manufacturing ownership, we provide the fixed configurations, deep engineering customization, and long-term supply stability required to turn your storage choice into a competitive advantage.