You’re looking for a solid state drive that is expected to run in a rugged industrial environment where temperatures swing radically; so, you pick an “I-Temp” rated SSD, confidently convinced that it will operate reliably as the specifications sheet states: from -40°C to 85°C. Yet, the drive fails. What went wrong? It wasn’t the number or the rating. It’s how the number was arrived at.

Clearly, not all industrial SSDs are created equal. This article explains why factors behind the spec matter more than the spec itself.

Thermal Specs More Than Meet the Eye

Behind every thermal rating lies a numerous collection of engineering decisions, test conditions, environmental factors, and several other factors. Here are some of the most important ones.

1. Tcase vs. Tambient Temperature. Specs sheets list an operating temperature range, which defines the specific lowest and highest limits within which the SSD can function reliably and consistently without getting damaged or losing its intended purpose.

Under heavy workloads, limited airflow, and poor thermal solutions, SSDs with I-Temp ratings qualified at Tambient may experience higher internal temperatures. ATP Electronics uses Tcase to qualify its SSDs to ensure that they perform safely, reliably, and consistently under extreme thermal challenges.

2. Operational vs. Non-Operational. Thermal specs may be labeled as “operating” (active) or “non-operating” (storage).

ATP SSDs are rigorously tested under full-load operating scenarios using real workloads to reflect actual use, making ATP specs more predictive in harsh environments. ATP SSDs have the ability to function within their published operating temperature limits and maintain their performance and reliability amidst extreme external conditions.

One of these functionality tests is Four-Corner Testing, which is performed at four quadrants of maximum/minimum operating temperature and input voltage. The SSDs are subjected to numerous cycles of high/low temperature and high/low voltage conditions.

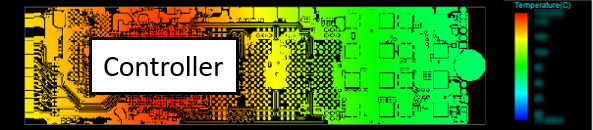

3. Sensor Location. Components within the SSD, such as the controller, NAND flash, and other components have varying thermal thresholds, which could be affected by their placements within the printed circuit board (PCB). If the sensor is far from the source, temperature readings may be inaccurate and underreported, causing performance reduction, overheating, and even data loss.

Accurate sensor place ensures precise monitoring of the hottest components, thus preventing them from exceeding their limits. This also allows heat management solutions to be implemented when the temperature reaches the threshold. The thermal sensors on ATP SSDs are positioned strategically to show true thermal data, while support for SMART attributes enables real-time thermal monitoring.

4. Cross-Temperature Robustness. While SSD specs label minimum and maximum thermal endpoints, actual operating conditions are not that straightforward. For drives installed in the uncontrolled edge, for example, temperatures can shift from hot to cold in an instant. Sometimes, the drives may be exposed to extreme heat or cold over prolonged periods. Such unpredictability can cause thermal shock and lead to failures.

ATP performs comprehensive cross-temperature testing to ensure that its SSDs perform reliably even while transitioning between extreme temperatures. Cross-temperature robustness is ensured and validated across different thermal cycles, not only in minimum and maximum limits.

ATP’s cross-temperature testing involves evaluating the NAND flash memory's performance and reliability under different combinations of high and low temperature conditions for write (program) and read operations. The testing consists of two scenarios:

- High Temperature (HT) Write with a known data pattern at 85°C and Low Temperature (LT) Read at -40°C. At this low temperature, the data will be read with read-retry techniques and compared with the original programmed data pattern.

- Low Temperature (LT) Write with a known data pattern at -40°C and High Temperature (HT) Read where the NAND flash is heated up to around 85°C or higher. At this high temperature, the data will be read with read-retry techniques and compared with the original programmed data pattern.

By analyzing the BER and other performance metrics under these cross-temperature conditions, we can assess the NAND flash memory's robustness, identify potential vulnerabilities, and determine its suitability for applications that require reliable operation across a wide temperature range.

With ATP’s thermal management technologies and cross-temp error handling solution, SSDs deliver data integrity and reliability during significant temperature fluctuations and even as the NAND approaches the end of its operational life.

5. Airflow. Airflow, typically measured in linear feet per minute (LFM), plays a crucial role in heat dissipation, especially for NVMe drives. LFM refers to the speed of airflow within a computer case. Known for their high-speed data transfer rates, NVMe drives generate increased heat during operation, NVMe SSDs require adequate cooling.

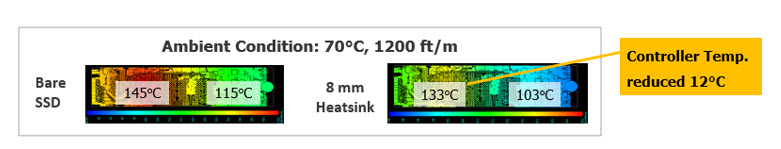

ATP defines airflow requirements for its NVMe drives and offers cooling solutions, such as heatsink options, to improve airflow and ensure adequate cooling. The following graph shows that controller temperature is significantly reduced with the following airflow conditions.

Conclusion: Make Sure What the Numbers Actually Mean

Temperature specifications are vital in determining an industrial SSD’s reliability in extreme environments. While these specifications may look the same across different SSDs, there is more than meets the eye. Customers should look beyond the face value of the numbers.

Factors to consider include ambient vs. case temperature, operational vs. non-operational (storage) temperature, sensor location, cross-temperature robustness, and airflow conditions. The next time you check out thermal specs, make sure what those numbers actually mean.

For inquiries about ATP’s thermal specifications for its wide range of memory and storage solutions, please visit the ATP website or contact an ATP representative in your area.