Edge computing refers to the processing and storage of data closer to the source, as opposed to centralized repositories like data centers. It enables data to be kept closer to its source or the network's edge. It speeds up access, processing, and response time by reducing the distance that the data must travel.

According to the International Data Corporation (IDC), worldwide spending on edge computing is expected to reach US$232 billion this year, maintaining strong growth through 2027 with spending reaching nearly US$350 billion.

As more systems and devices become interconnected, the high amount of data being stored and exchanged poses technical, physical, and environmental challenges to storage solutions.Neither traditional industrial nor enterprise SSDs perfectly fit the needs of Edge computing.

Edge Storage Requirements in the Industrial Enterprise

Environmental Resilience

Edge storage devices may be deployed anywhere from controlled indoor settings like offices, hospitals, and factories to rugged, remote, and uncontrolled settings like autonomous vehicles, oil and gas plants, smart energy grids, and roads.With the wide variety of usages, applications, and locations, edge storage devices should be able to endure harsh weather conditions, extreme temperatures, shocks, vibration, and other challenges.

ATP Ensures Design/Product Characterization and Specification Validation to Achieve Design Reliability through Extensive Testing

Enterprise Readiness

Storage devices at the edge are expected to handle enterprise-level workloads; hence, standards should be at par with server, storage, and data center SSDs.Enterprise SSDs must meet the expected use cases and testing methods set by JEDEC according to its SSD standards, such as the JESD218A “Solid State Drive (SSD) Requirements and Endurance Test Methods” and JESD219 “Solid State Drive (SSD) Endurance Workloads.”They should maintain the highest levels of data reliability, availability, and integrity even while operating continuously, 24/7. They should also be able to withstand heavy read or write operations.

The graph above shows nine typical enterprise workloads. ATP recognizes the diverse requirements of these workloads and performs suitable testing to ensure that SSD performance

Endurance and Reliability

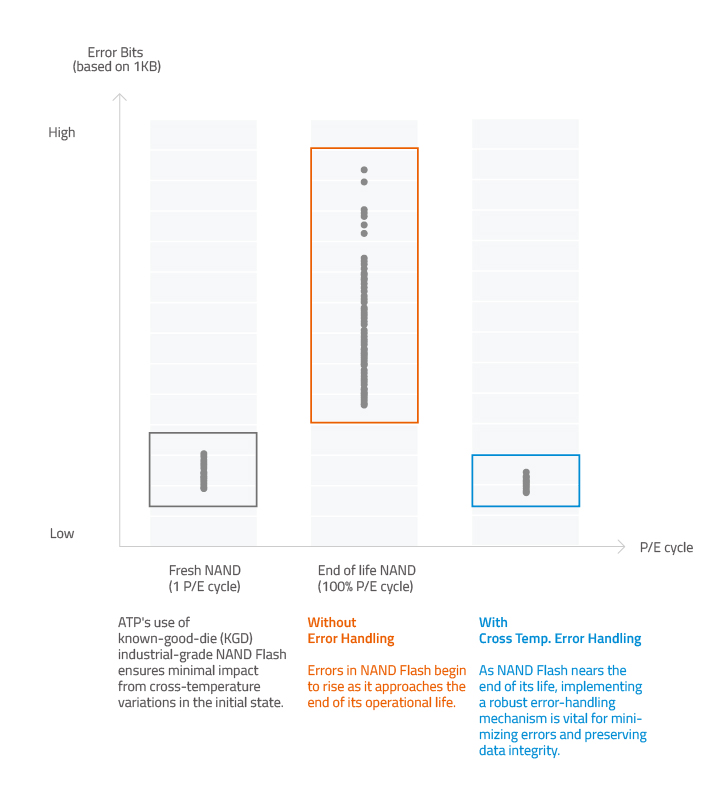

To prevent premature wearout and to protect the reliability of stored data, SSDs deployed at the edge require powerful cross-temperature error handling, power failure protection, and end-to-end data protection technologies are crucial considerations to ensure reliable performance for many years.

ATP has developed technology to mitigate errors that can occur when SSDs operate across varying temperatures. This is particularly important for scenarios where data is written at low temperatures (-40°C) but read at high temperatures (85°C), which can increase error rates and potentially compromise data integrity over time. ATP's solution helps maintain data integrity even as the NAND approaches the end of its operational life.

ATP Offers the Best of Both Worlds: Into the Edge, Beyond the Walls of the Datacenter

ATP Electronics is thrilled to introduce a new product class like no other:THE INDUSTRIAL ENTERPRISE SERIES.

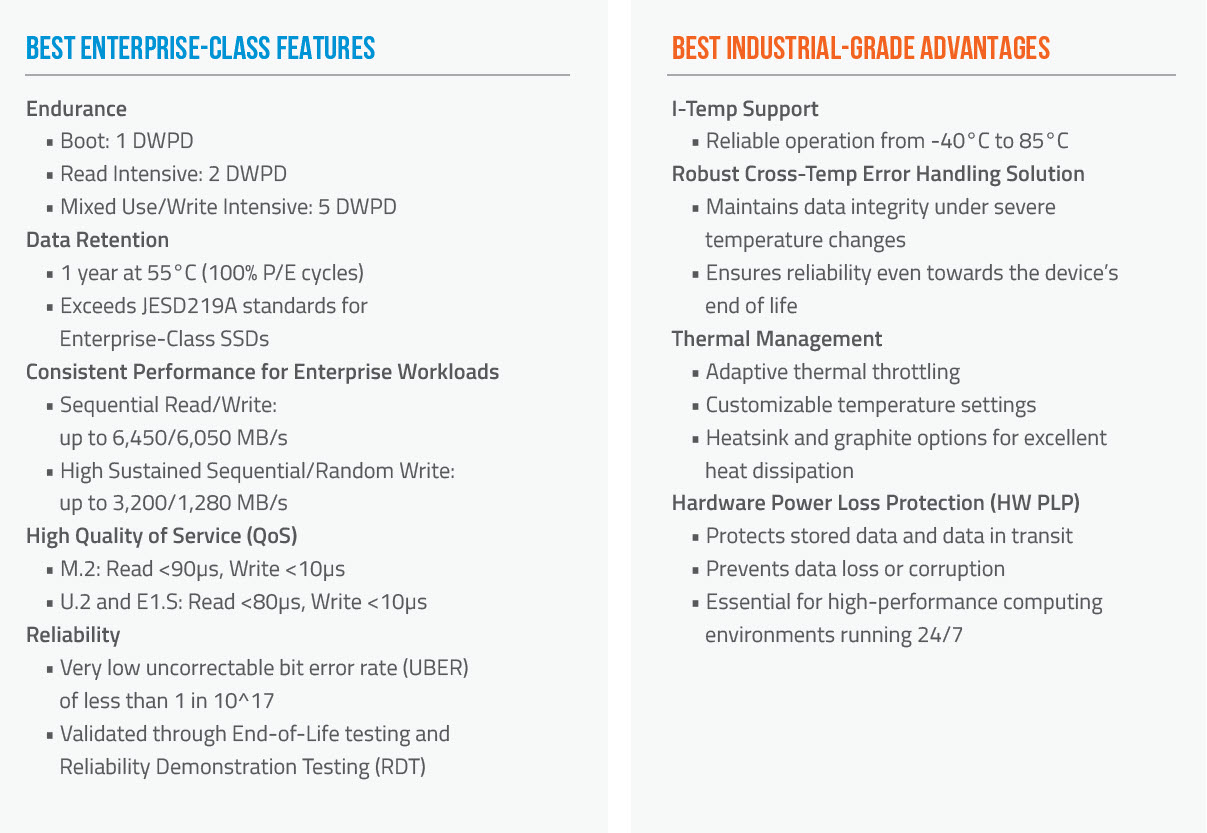

It combines the greatest features of both enterprise class and industrial grade SSDs for unparalleled storage in uncontrolled environments.

The Best of Both Worlds

The Industrial Enterprise N651Sie Series SSDs leverage NVMe PCIe Gen4x 4 and are available as M.2, U.2, and E1.S. They are built for enterprises generating massive amounts of data and processing them at uncontrolled environments closer to the source. Incorporating the best enterprise class and industrial grade features, they make great boot drives, data storage drives, or mixed-use drives.

WE BUILD WITH YOU Firmware Customization Service

Under ATP’s WE BUILD WITH YOU program, the following enhanced Firmware Customization Services are available on a project basis to meet various enterprise customer needs in Server, Storage and Compute.

- Performance Behavior Tuning. Performance behavior analysis and customization to optimize throughput and latency in a customer host application.

- Power Loss Protection (PLP) Tuning

- Optimized Flush Cache Timing. Ensures that the flush cache is completed within the capacitors’ hold-up time to ensure the integrity of data in flight and at rest.

- PLP Capacitor Monitoring. Performed using the onboard microcontroller unit (MCU), includes regular capacitor health checks during SSD bootup and operation.

Thermal Management Customization. ATP’s adaptive thermal throttling solution is distinguished by the ability to adjust the temperature settings according to the customer’s application-specific requirements.

- Enhanced Read Disturb Resilience. The ATP FW monitors and refreshes frequently read and read-only data by moving it to another block when the error criteria or threshold is met. ATP can modify the FW to enhance its ability to withstand Read Disturb events in specific Enterprise use cases, such as Boot-Up Scenarios.

- SMART ID Customization. The firmware includes a range of Self-Monitoring, Analysis and Reporting Technology (SMART) ID attributes that can be customized based on customer requirements.

- Download Microcode Capability. This service is part of flexible firmware maintenance, enabling Enterprise customers to rapidly make updates to their specific configurations via field updates, avoiding the hassle of sending SSDs back to ATP for reinitialization.

Conclusion

The world is increasingly becoming connected, and devices are generating huge amounts of data, necessitating enterprises to move storage and processing to distributed locations closer to the source. With edge computing, data storage devices can be anywhere, making them susceptible to environmental challenges that could compromise their endurance, reliability, and data integrity.

ATP Electronics has risen up to these challenges with the introduction of the INDUSTRIAL ENTERPRISE SERIES SSDs. These SSDs integrate the best of enterprise class and industrial grade features for effective and efficient storage in uncontrolled environments beyond the walls of datacenters.

For more information on ATP’s Industrial Enterprise SSDs, contact a Representative or Distributor In your area.