“Prevention is better than cure.” This is true, not only for preventing illnesses, but also for data that may be compromised or lost forever because of unmonitored capacitor health. Hardware Power Loss Protection (HW PLP) with capacitors is crucial for safeguarding in-flight data during power outages. These capacitors provide holdup power long enough for the host to flush data in the cached into the solid state drive (SSD) for safe storage. However, capacitors can age or fail over time, making the HW PLP feature ineffective, putting the in-flight data at risk. Worse, users may not be aware that the capacitors may have already been malfunctioning for some time without any remedy at hand.

Why Proactive Monitoring Matters: How Healthy are Your SSD’s PLP Capacitors?

Regular laboratory checks and doctor visits are very important to everyone’s health. They help identify early warning signs of disease or illness, enabling early intervention and successful treatment.

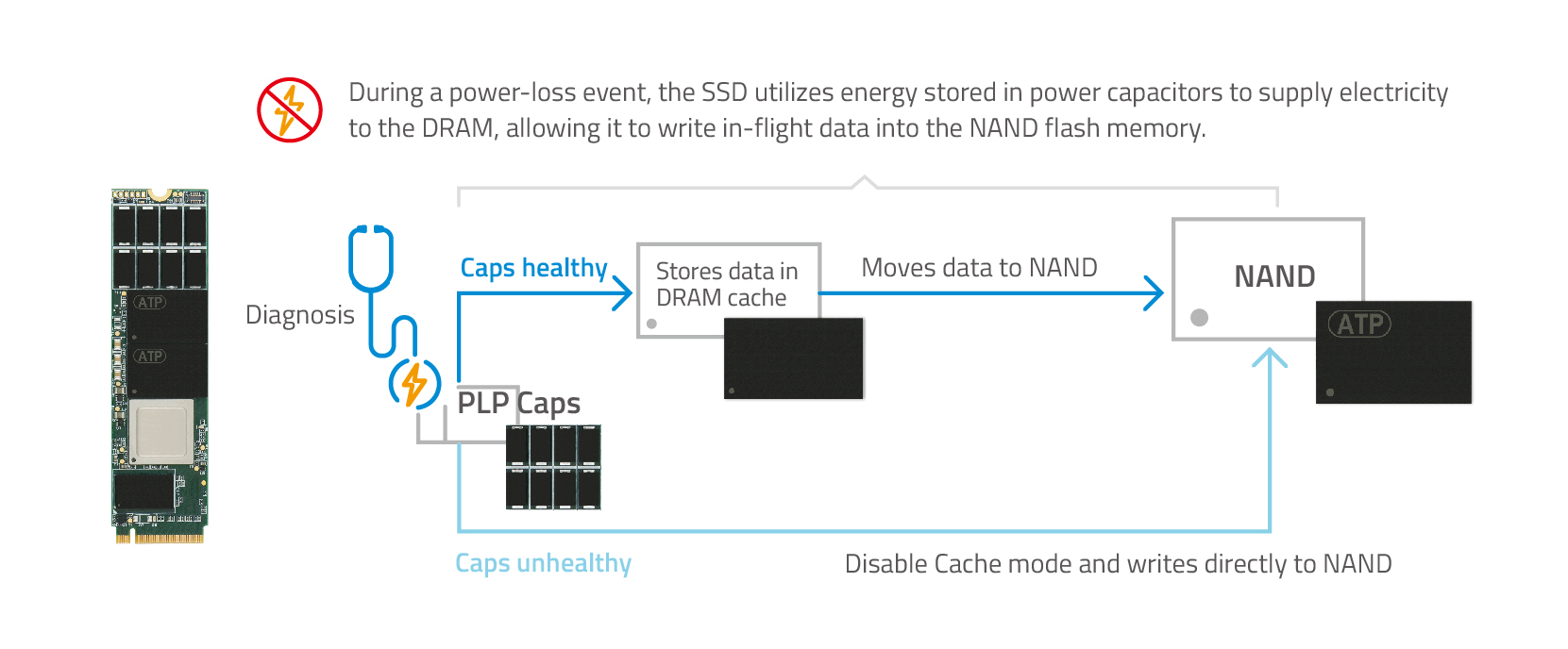

For solid state drives (SSDs), HW PLP mechanisms safeguard against data loss during sudden power loss events by using capacitors that ensure efficient power supply during the critical process of flushing DRAM cache data to the NAND, protecting valuable information during unexpected sudden-power-loss scenarios.

Common Causes of Capacitor Failure

What people might not realize is that capacitors of any kind may age and/or fail over time due to:

- Dielectric breakdown, which is the inability of an insulating substance to stop current flow when electrical stress is applied, short-circuiting the capacitor

- Mechanical stresses causing cracks, defects, or damages

- Environmental extremes such as high or fluctuating temperatures accelerate breakdown

- Voltage/current stresses. Operating beyond design specifications can speed up deterioration

- Aging and wear. Repeated charge/discharge cycles degrade performance

What is more concerning is that users may remain unaware that their SSD's power loss protection has been compromised, potentially putting their data at risk without their knowledge.

Consequences of Unmonitored Capacitor Health

When capacitors fail without being detected, the following things may happen:

- PLP Failure. When capacitor functionality is compromised, the PLP mechanism is unable to safely move data from the cache to the SSD, risking loss or corruption.

- Data Integrity Issues. If the cached data is not safely transmitted to the SSD, critical information may be jeopardized.

- Shorter SSD Lifespan. Persistent and prolonged operation under compromised conditions will hasten SSD degradation.

- Operational Losses. Increased downtime, unpredictable system crashes, and disrupted operations lead not only to data loss but losses to the bottom line as well.

The Doctor is In: ATP PLP Diag Proactive Capacitor Health Monitoring

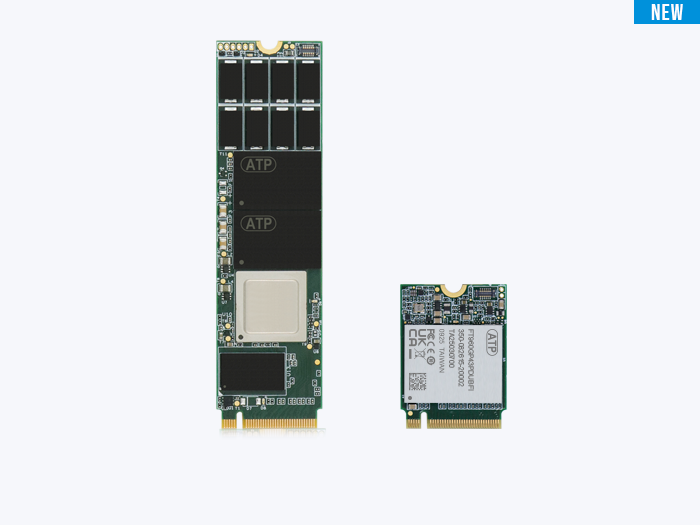

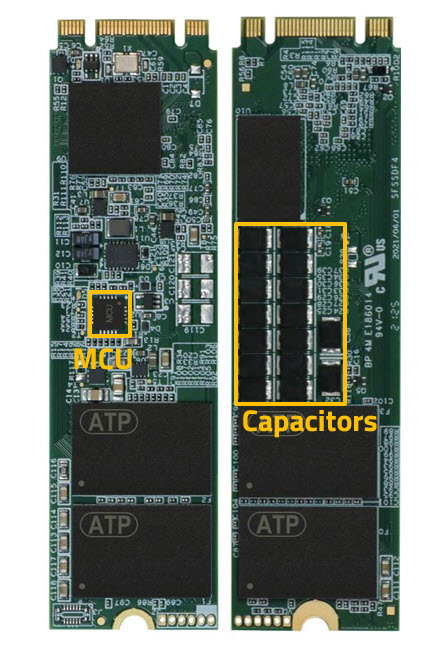

ATP HW PLP components use high-quality polymer tantalum capacitors and a microcontroller unit (MCU) to minimize instabilities. Providing an extra layer of protection is a new, ATP-exclusive technology called “PLP Diag.”

The ATP PLP Diag Technology proactively checks capacitor health and functionality, preventing failed PLP burnout and ensuring data integrity. (The actual mechanism may differ across SKUs.

When the MCU determines that the capacitors are no longer healthy:

- Bypass DRAM Cache. The SSD aborts the first write CMD and disable the write cache as this temporary storage is dependent on the capacitor’s holdup power to flush data.

- Use Direct Write to TLC. The SSD then resumes writing to the TLC NAND in direct mode.

Two Ways to Diagnose

- Automatic Check. SSDs automatically check the PLP status and react to faulty statuses to avoid burning out or exposing in-flight data to the risk of corruption or loss.

- SMART CMD Integration. Users may issue a SMART command (CMD) to verify the PLP status themselves.

PLP Diag Benefits: Health is Wealth

Proactive preparedness is paramount in maintaining data integrity and system reliability. ATP PLP Diag offers the following benefits:

- Richer Data Protection and Integrity. By constantly monitoring capacitor health, proactively diagnosing any issues, and taking preemptive measures, PLP Diag ensures the success of the PLP mechanism in protecting data.

- Minimal Downtime and Maximum Reliability. Real-time capacitor health monitoring and diagnosis help prevent unplanned downtime, keeping both the system and storage device reliable at all times.

- Longer SSD Lifespan. Early detection of capacitor defects ultimately cascades to optimized SSD performance and endurance.

- SMART Integration. By allowing users to check the PLP status through SMART commands, PLP Diag offers easy, convenient, and proactive maintenance of their device reliability.

Use Case Scenario 1: Capacitor Failure Jeopardizes Server Operation

Background

In-flight data protection via HW PLP is a standard feature of a server manufacturer’s SSD drives. Over time, a certain percentage of SSD malfunctions have been identified as being caused by capacitor failures.

Problem

Capacitor health is usually not monitored, so capacitor failures often go unnoticed by server users or maintenance services. These failures are only discovered when end-to-end data (E2E) errors occur during power cycle events. The SSD is then sent back to the vendor for analysis. In rare cases, a capacitor failure combined with overcharging can result in burns and pose a risk to the entire server’s safety.

ATP Solution

ATP PLP Diag prevents capacitor overcharging by automatically checking the capacitor status and switching to Direct Mode in the event of an unpredictable but potential capacitor failure. As the users themselves can check the status and functionality of the capacitors, they do not need to send the SSD back to the vendor, preventing downtime and disruption in the operations.

Use Case Scenario 2: Sudden Power Loss Events Often Challenge PLP in an OT Environment

Background

In an Operational Technology (OT) environment, Sudden Power Loss events often challenge the SSD’s HW PLP mechanism. These environments frequently experience abrupt power interruptions due to constraints in legacy embedded systems or sub-systems, which can test the robustness of PLP features in SSDs and other storage devices.

Problem

PLP failure rates are higher in frequent power on/off cycles, whether normal or unexpected. As subsystems are often scattered and decentralized, they are expected to operate unnoticed and unattended. Users realize that they essentially have no way to detect any failed PLP on SSDs installed within these systems. No industrial SSD vendor addresses the constant risk they are exposed to.

ATP Solution

By using ATP SSDs with PLP Diag, embedded users can rely on the SSD to manage already-reduced PLP failures. It automatically checks the capacitor status and switches to Direct Mode in the event of a capacitor failure without disabling onsite operations. Users can leave the SSD unattended until the scheduled routine maintenance and check if any replacement is required.

Conclusion

As more industries and enterprises rely on SSDs for reliable data storage under all circumstances, especially during unpredictable power loss events, ATP Electronics strengthens its SSDs’ MCU-based HW PLP design with PLP Diag.

By proactively monitoring the health of its polymer tantalum capacitors and responding to potential failures that expose the in-flight data to risks, PLP Diag offers fail-safe protection to ensure uncompromised data integrity and device reliability.

For more information on the ATP PLP Diag Technology, visit the ATP website or contact an ATP Representative in your area.