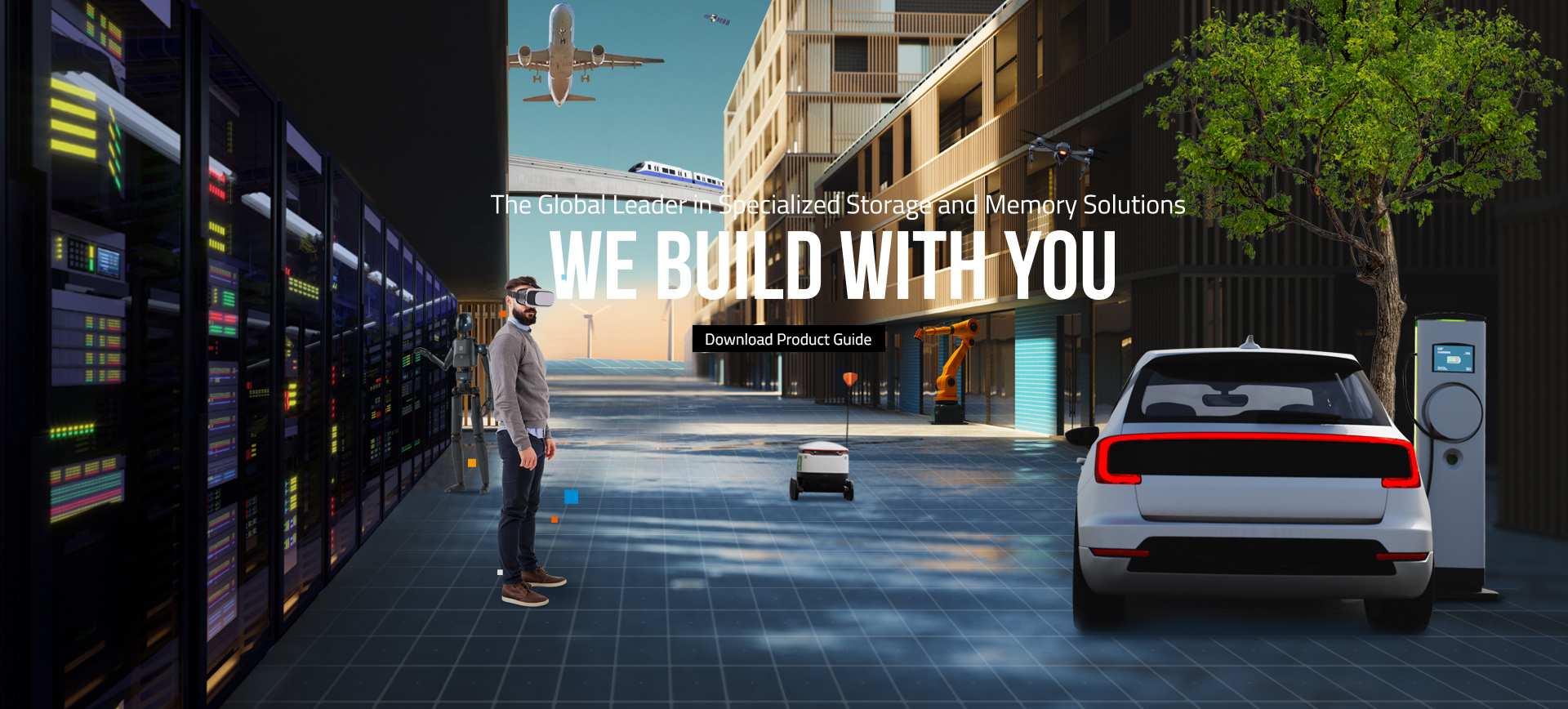

NAND Flash and DRAM solutions

最も要求の厳しい産業用アプリケーションに対応する妥協を許さない信頼性と耐久性

ネットワーク / テレコム

メモリと NAND フラッシュ ストレージの要件が高まる中、ネットワークおよび電気通信業界は、30 年以上前と同様に ATP Electronics を信頼し続けています。 今日、プライマリ ストレージ、データ センターとクラウド コンピューティング、および WAN エッジ インフラストラクチャに関する Gartner の Magic Quadrant レポートに記載されている企業の 70% 以上が、ATP を戦略的サプライヤーと見なしています。

詳しい情報オートモーティブの用途

自動車は通常、様々な気候や気温環境下でネットワーク接続がほとんど、もしくは全く無いエリアを走行しながら膨大なデータ量を絶えず生成・記録します。それ故に車載ストレージは必 要なときに利用できるように、このデータを正確、且つ安全に保持する能力が求められます。

詳しい情報防衛/航空宇宙

ATP Electronics は、航空宇宙分野向けのメモリおよびストレージ デバイスの最適化を専門としています。 ATP は、大量の最小注文数量 (MOQ) を必要とせず、耐久性、堅牢性、および高持久性のソリューションの包括的なポートフォリオを提供します。 これらのソリューションには、特定のアプリケーションの要件を満たすために綿密にテストされたインダストリアルグレードでカスタマイズされた商用オフザシェルフ (COTS) モジュールが含まれています。

詳しい情報産業機器 / オートメーション

ATP は、産業機器および自動化システムの厳しい要件を満たすさまざまなフォーム ファクターで、レガシーおよび最新世代のメモリおよび NAND フラッシュ ストレージ ソリューションを幅広く提供します。最長の稼働時間と最小限のメンテナンスを提供するように構築されたこれらのソリューションは、過酷な条件下や極端な温度下でも確実に動作します

詳しい情報交通機関

輸送はサプライ チェーン管理において重要な役割を果たします。 したがって、商品やサービスをタイムリーに提供することは困難な課題になる可能性があります。データ技術、人工知能 (AI)、およびその他の技術の進歩により、輸送システムは最適なコストでより効率的に運用され、より優れたサービスを提供できるようになってきています。これらの進歩の中心にあるのは、より優れたフリート管理、予測分析、およびスマー ロジスティクスを可能にするメモリおよびデータ ストレージ ソリューションです。

詳しい情報- ネットワーク / テレコム

- オートモーティブの用途

- 防衛/航空宇宙

- 産業機器 / オートメーション

- 交通機関

最近のアップデート

イベントカレンダー

Embedded World 2026

Hall 1-212

ATP Electronics,showcases its Specialized Storage & Memory Solutions at Embedded World 2026

イベント

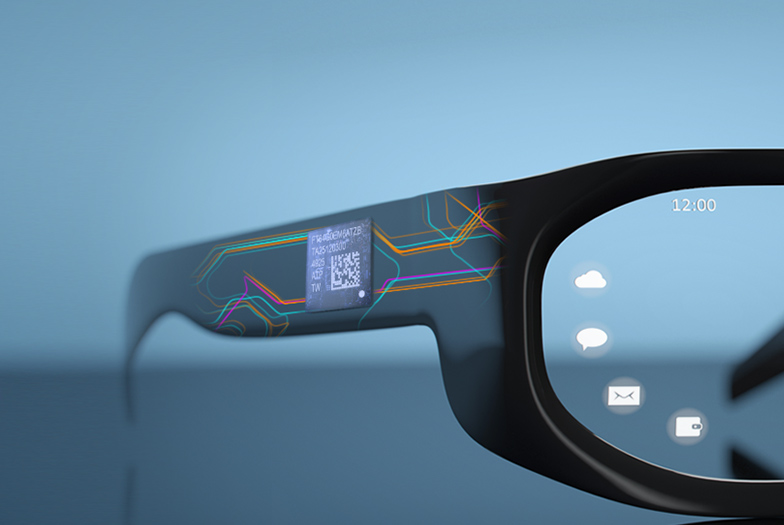

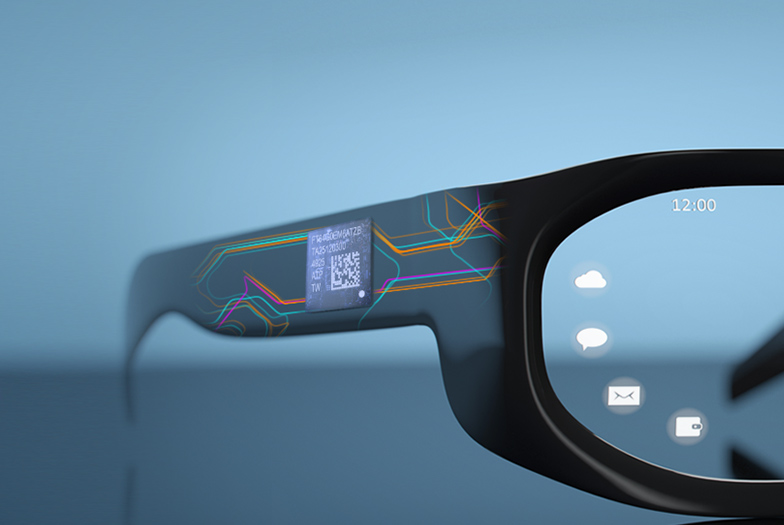

ATPエレクトロニクス 次世代スマートウェアラブル用途に最適な 世界最小で世界初の6.7mm e.MMCを発表

新しいフォームファクタは、スリムな長方形のフレームを持つスマートグラスを考慮し、パッケージ高さを0.65mmと薄く設計することで、スマートグラスの技術的、人間工学的、そして美的特徴に完璧に溶け込みます。さらに、6.7mm e.MMCは、単体のローパワーダブルデータレート(LPDDR)メモリや主要なシステムオンチップ(SoC)プラットフォームと組み合わせることができ、スマートグラスのスリムなデザインと高度なパフォーマンス要件をサポートする、超小型で効率的なメモリソリューションを提供します。

ATP Anzcham Charity Bike Ride

After 5 incredible days and 538 km 🚴♂️🚴♂️🚴♂️, ATP Representatives and fellow participants crossed the finish line in Tainan today!

What Procurement Teams Need to Know Before Buying Industrial SSDs

Discover how engineers and procurement teams can align on industrial SSD selection to ensure reliability, longevity, and lower total cost of ownership.

Memory Wars: Why HBM Is the Hottest Commodity in AI

CONNECTED presenter Susan Chow engages in an insightful conversation with ATP Electronics President and CEO Jeffray Hsieh at COMPUTEX/InnoVEX 2025.

ATP Electronics Publishes Its First Sustainability Report, Marking a Corporate Responsibility Milestone

ATP supports mission-critical systems with reliability at the core—driving our commitment to sustainability and our first Sustainability Report.

もっと読むATP Electronics: Committed to a PFAS-Free Future for Your Safety and the Environment

At ATP Electronics, we are committed to the safety and well-being of our customers and the environment. We understand the growing concern regarding Per- and polyfluorinated alkyl substances, or PFAS, and their widespread use in consumer products. These pe

もっと読むSmart Factories: The Color of the Future is Green

As a true manufacturer, ATP Electronics recognizes that smart manufacturing is a leading driver of ESG. Policies on the environment and sustainability continue to increase in importance amid critical concerns such as climate change.

もっと読むATP Electronics Shows Support for Vulnerable Children,Joins Chung Yi Social Welfare Foundation Fundraiser to Build New Orphanage

The charity event, “Putting Effort Into Love Homes,” was aimed to promote awareness of Chung Yi Social Welfare Foundation’s advocacy to provide warm homes and professional services for vulnerable children and to raise funds for building new orphanages.

もっと読むATP Electronics Spreads the Warmth of Love and Sharing at NCCU Auction Banquet

ATP was privileged to have had the opportunity to participate in a charity auction that aimed to benefit two humanitarian foundations for people with special needs.

もっと読むWinning the Flash Memory and Storage Circuit: Lessons from the Racetrack

The industrial and embedded segment may be likened to motorsports racing, where choosing the right car and car settings for the right racetrack is critical to winning.

もっと読むNVMe SSD Thermal Management: What We Have Learned from Marathons

Marathons and the thermal throttling management of NVMe SSDs have these five things in common, each of which can impact performance

もっと読むATP SATA SSDs Qualify for Compatibility and Interoperability with Microchip’s New Tri-Mode Storage Adapters

ATP's A600Sc Series serial ATA solid state drives (SATA SSDs) have been successfully qualified for compatibility and interoperability with Adaptec® Smart Storage PCIe® Gen 4 Tri-Mode SmartRAID 3200, SmartHBA 2200, and HBA 1200 Smart Storage adapters.

もっと読むATP is committed to protecting your privacy. To meet the requirements of the new EU General Data Protection Regulation (GDPR), we have updated our Privacy Policy to let you know how we collect data to deliver enhanced content and experience on the ATP site.