Industrial SSDs, SD NAND Flash products and DRAM Modules

Uncompromising Reliability and Endurance for the Most Demanding Industrial Applications.

Networking / Telecom

Learn why over 70% of companies listed on Gartner’s Magic Quadrant report for Primary Storage, Data Center and Cloud Computing, and WAN-Edge Infrastructure consider ATP as a strategic supplier.

Learn MoreAutomotive

Automotive applications need robust memory and storage solutions that can hurdle rigorous environmental, power and thermal challenges to ensure safer and more comfortable driving.

Learn MoreDefense / Aerospace

The Aerospace segment often stands shoulder to shoulder with Defense and share many of the same challenges, including extreme temperatures, shock/vibration, and harsh environments.

Learn MoreIndustrial / Automation

ATP offers a full spectrum of legacy and latest-generation memory and NAND flash storage solutions in a variety of form factors that meet the stringent requirements of industrial and automation systems

Learn MoreTransportation

For public transportation systems, our fundamental competitiveness in endurance, longevity, wide-temp, fix BOM control, and delivers suitable industrial storage and memory solutions.

Learn More- Networking / Telecom

- Automotive

- Defense / Aerospace

- Industrial / Automation

- Transportation

Recent Updates

Event Calendar

Embedded World 2026

Hall 1-212

ATP Electronics,showcases its Specialized Storage & Memory Solutions at Embedded World 2026

All Events

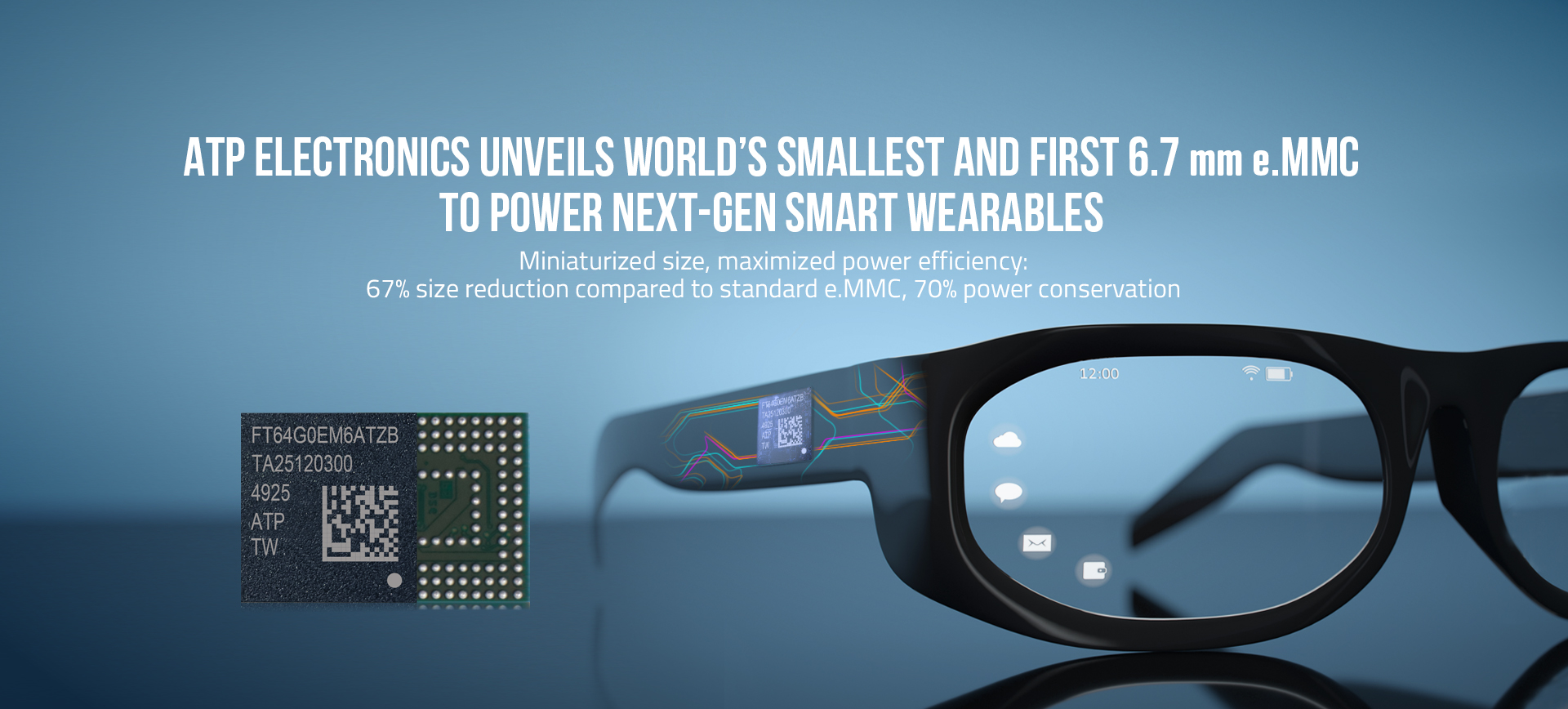

ATP Electronics at Embedded World 2026: Redefining Wearable Storage, Endurance, Memory Reliability

ATP Electronics will debut the World’s Smallest 6.7 mm e.MMC at Embedded World 2026.

ATP Anzcham Charity Bike Ride

After 5 incredible days and 538 km 🚴♂️🚴♂️🚴♂️, ATP Representatives and fellow participants crossed the finish line in Tainan today!

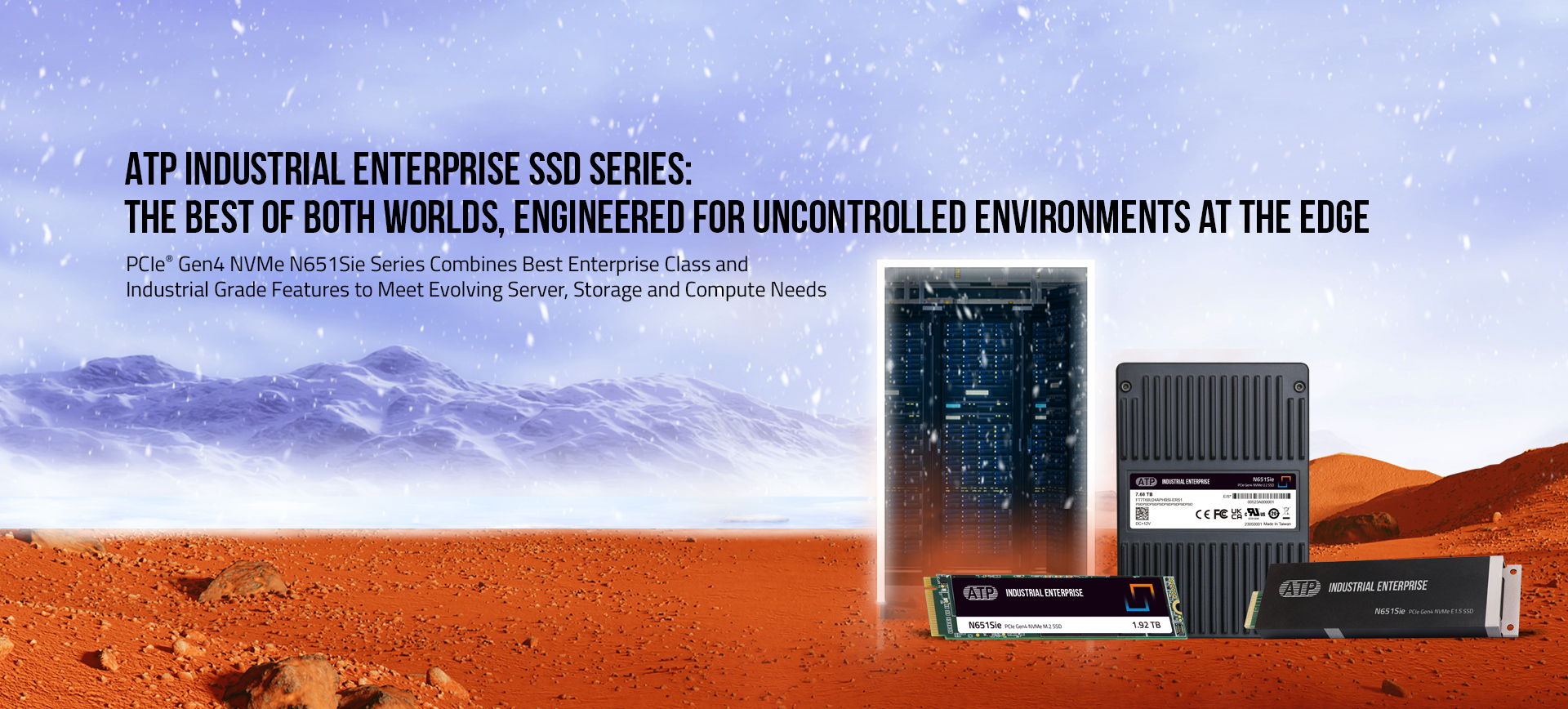

What Procurement Teams Need to Know Before Buying Industrial SSDs

Discover how engineers and procurement teams can align on industrial SSD selection to ensure reliability, longevity, and lower total cost of ownership.

Memory Wars: Why HBM Is the Hottest Commodity in AI

CONNECTED presenter Susan Chow engages in an insightful conversation with ATP Electronics President and CEO Jeffray Hsieh at COMPUTEX/InnoVEX 2025.

ATP Electronics Publishes Its First Sustainability Report, Marking a Corporate Responsibility Milestone

ATP supports mission-critical systems with reliability at the core—driving our commitment to sustainability and our first Sustainability Report.

Read moreJapan Office Relocation Notice

ATP Electronics Japan, Ltd., are pleased to announce that our office will be relocating to a new address.

Read moreATP Electronics: Committed to a PFAS-Free Future for Your Safety and the Environment

At ATP Electronics, we are committed to the safety and well-being of our customers and the environment. We understand the growing concern regarding Per- and polyfluorinated alkyl substances, or PFAS, and their widespread use in consumer products. These pe

Read moreSmart Factories: The Color of the Future is Green

As a true manufacturer, ATP Electronics recognizes that smart manufacturing is a leading driver of ESG. Policies on the environment and sustainability continue to increase in importance amid critical concerns such as climate change.

Read moreATP Electronics Shows Support for Vulnerable Children,Joins Chung Yi Social Welfare Foundation Fundraiser to Build New Orphanage

The charity event, “Putting Effort Into Love Homes,” was aimed to promote awareness of Chung Yi Social Welfare Foundation’s advocacy to provide warm homes and professional services for vulnerable children and to raise funds for building new orphanages.

Read moreATP Electronics Spreads the Warmth of Love and Sharing at NCCU Auction Banquet

ATP was privileged to have had the opportunity to participate in a charity auction that aimed to benefit two humanitarian foundations for people with special needs.

Read moreWinning the Flash Memory and Storage Circuit: Lessons from the Racetrack

The industrial and embedded segment may be likened to motorsports racing, where choosing the right car and car settings for the right racetrack is critical to winning.

Read moreNVMe SSD Thermal Management: What We Have Learned from Marathons

Marathons and the thermal throttling management of NVMe SSDs have these five things in common, each of which can impact performance

Read moreATP SATA SSDs Qualify for Compatibility and Interoperability with Microchip’s New Tri-Mode Storage Adapters

ATP's A600Sc Series serial ATA solid state drives (SATA SSDs) have been successfully qualified for compatibility and interoperability with Adaptec® Smart Storage PCIe® Gen 4 Tri-Mode SmartRAID 3200, SmartHBA 2200, and HBA 1200 Smart Storage adapters.

Read moreATP is committed to protecting your privacy. To meet the requirements of the new EU General Data Protection Regulation (GDPR), we have updated our Privacy Policy to let you know how we collect data to deliver enhanced content and experience on the ATP site.